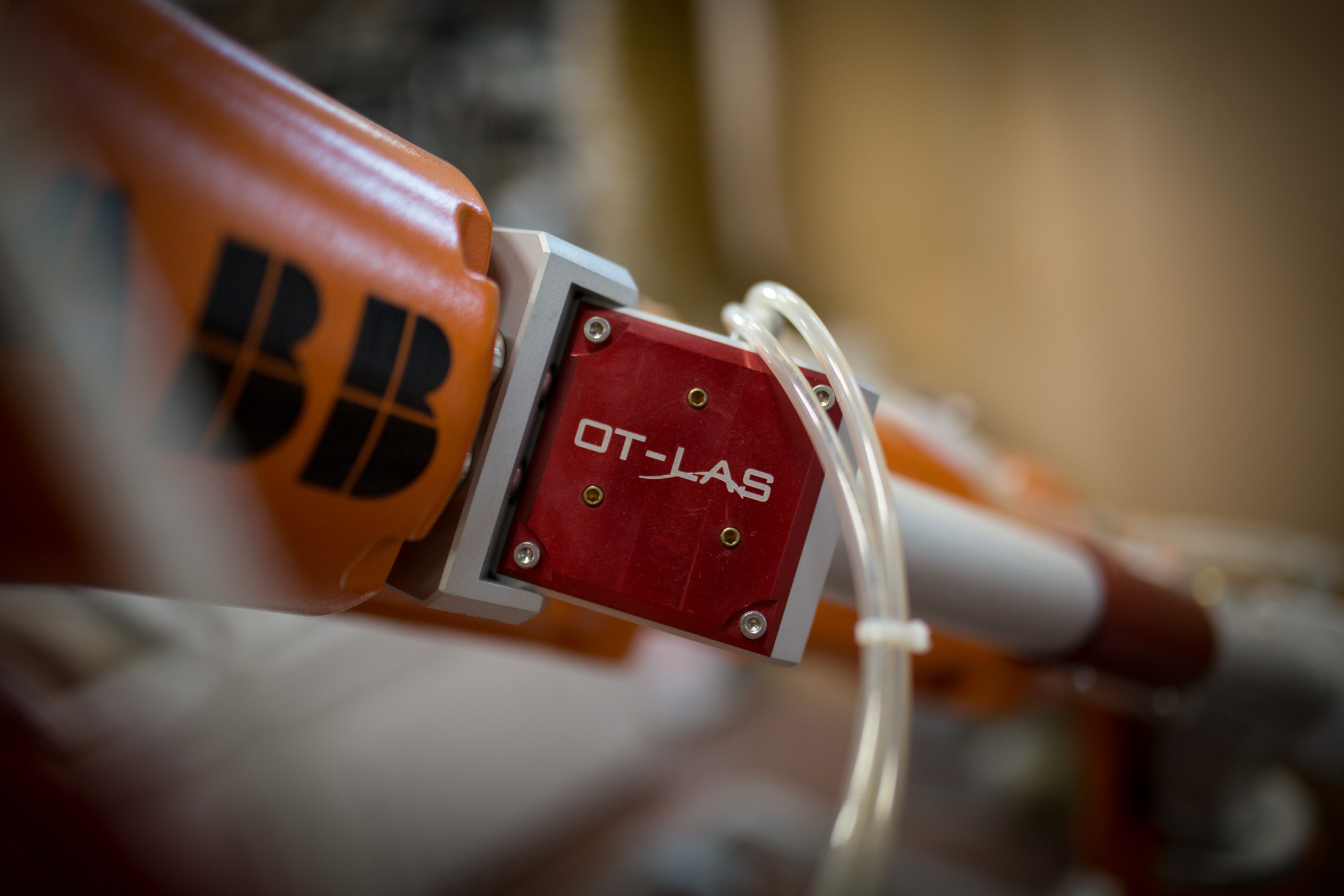

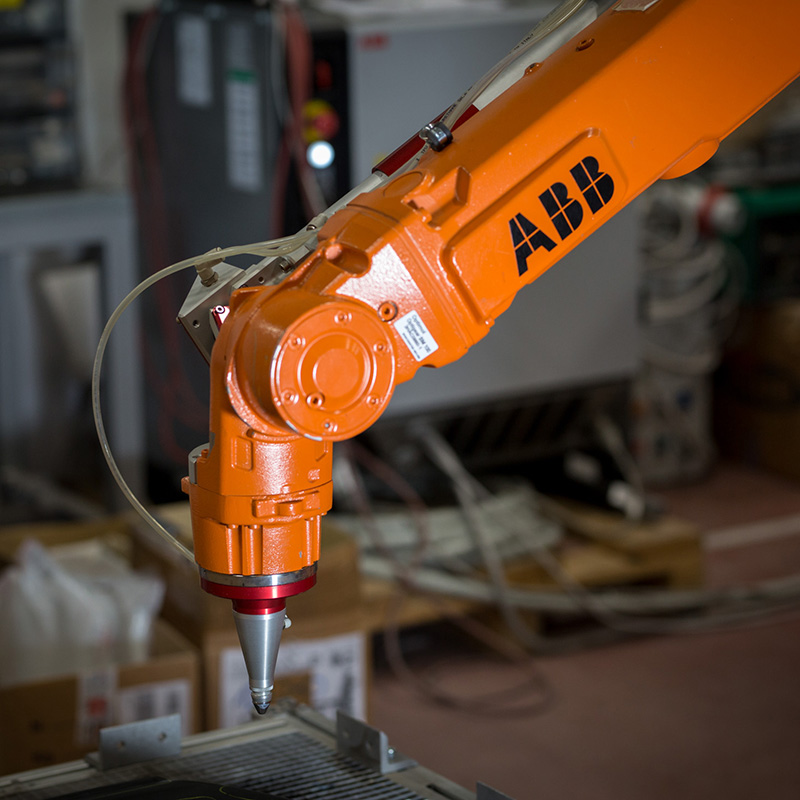

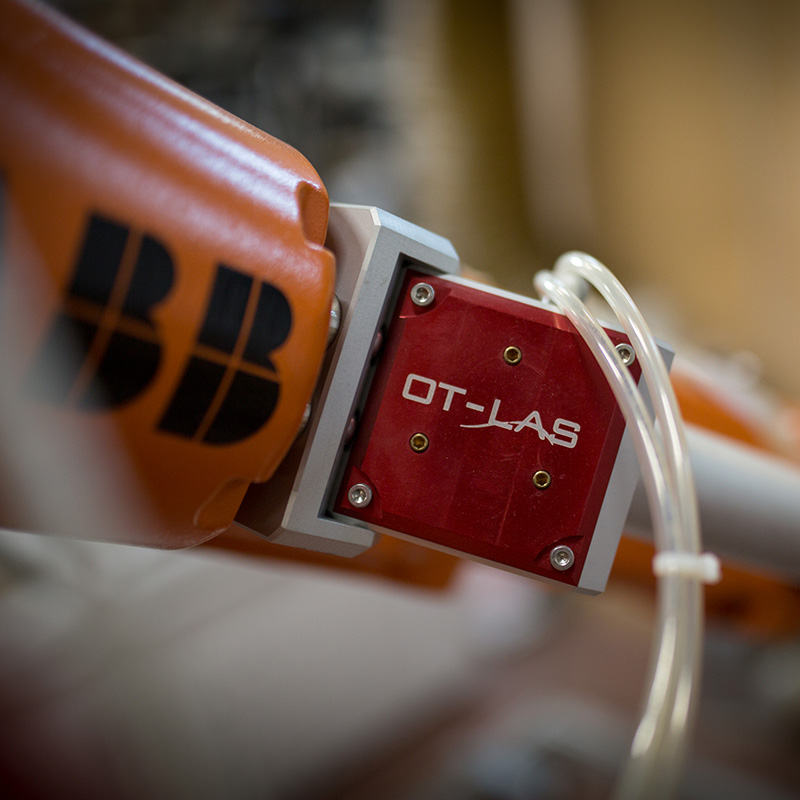

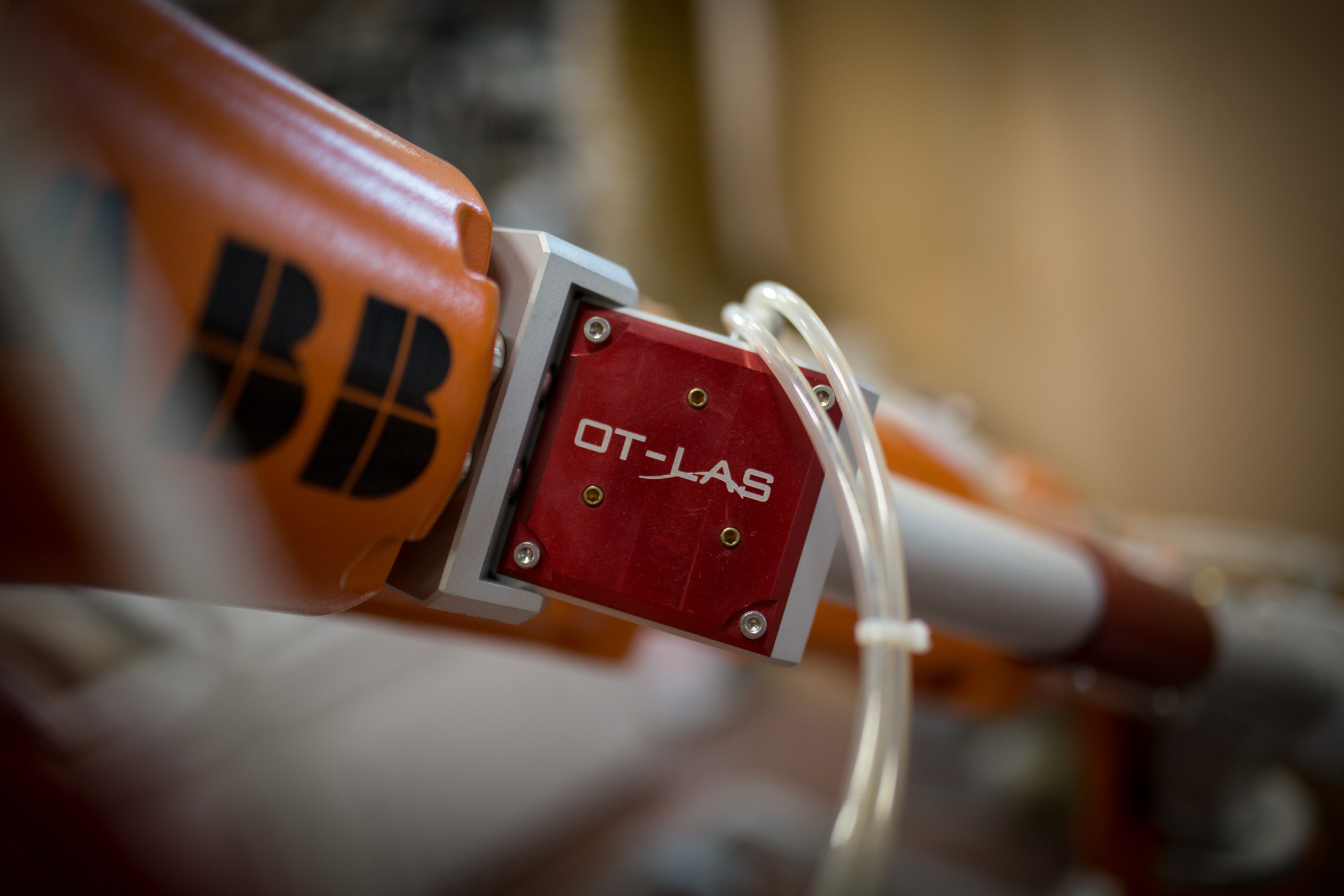

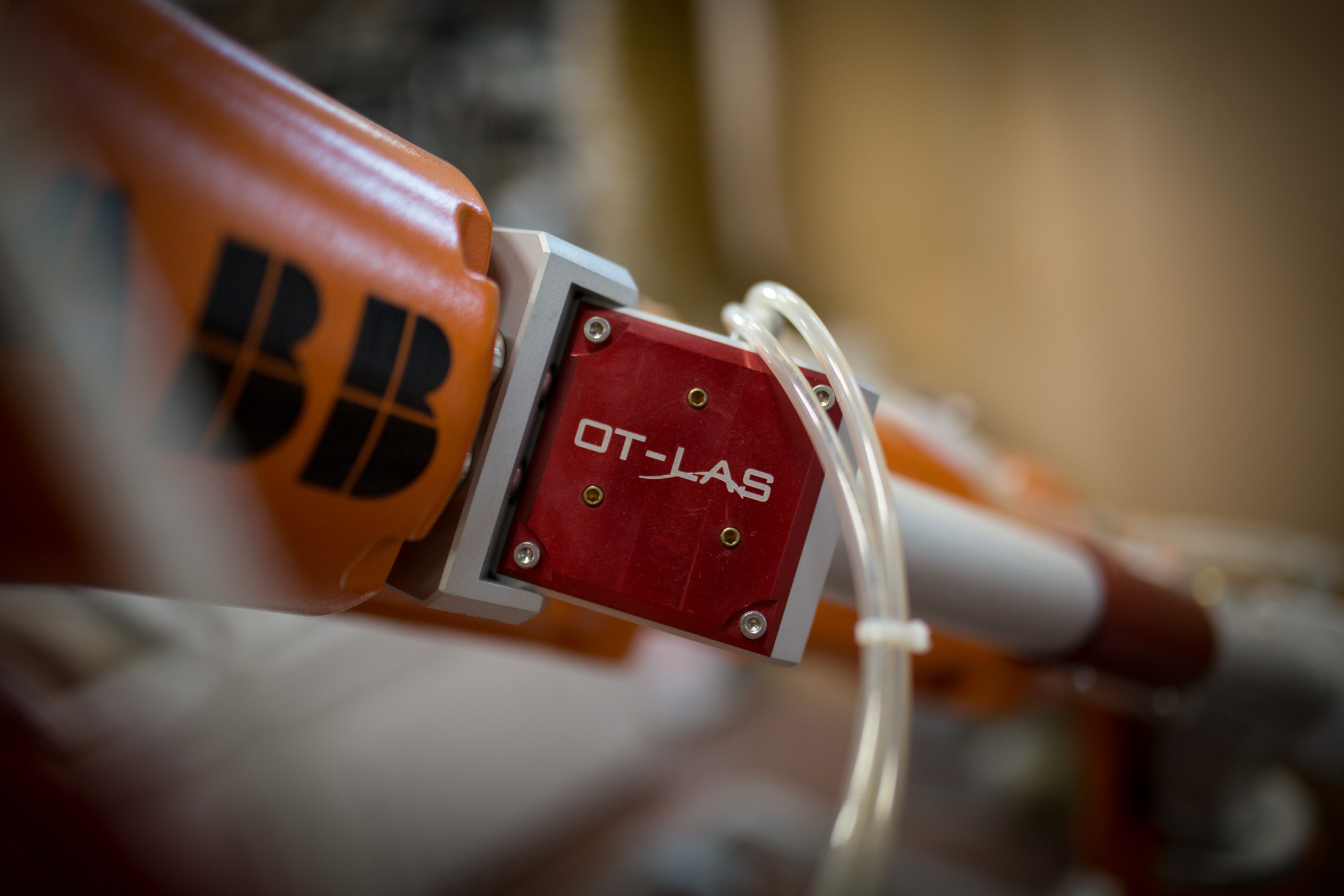

Laser cutting robot for 3D finishing of plastics

The CO2 laser is particularly recommended for 3D cutting finishing of thermoformed, printed or blown plastics, as it allows obtaining

Thermoforming is a technique of hot molding widely used in the realization of industrial molds. Through the laser machine application extremely accurate and neat cutting and finishing are carried out of thermoformed, ABS and composite materials, thus also being suitable for high-profile processing. Compared with the traditional finishing techniques, the laser considerably reduces processing time guaranteeing very-high quality and non-frayed edges. The laser machine efficiency also allows a lower use of power resources, thus considerably reducing the environmental impact of processing. In fact, compared with other cutting systems, it does not use materials that are to be disposed of, as it happens with water-jet for instance.

The OT-LAS laser machines are suitable for processing of all plastics/eco-plastics, ABS, carbon, foam materials, resins. The typical high accuracy of the cutting and engraving systems make them the ideal solution also for the finishing of internal components of motor-vehicles, fridges and freezers, motorcycle helmets and many other applications.

Materials suitable for thermoforming laser machines:

Our laser machines for thermoformed and composite materials are designed and developed in-house so as to deliver the best performance. High technology of components along with unique assembly allow extraordinarily versatile processing, that could not be realized by means of other systems. An example is our RX system that, coupled with a robot, offers all the flexibility typical of a 5-axis system. The extraordinarily free joint of the mechanical arm and the small-sized focusing head bring about the maximum extent of motion during processing to cut the piece in positions that would otherwise be very difficult to access by other systems. The high accuracy of the optical arm organized into 7 mirrors guarantees perfect finishing with no deburring or fraying. Furthermore, the auto-focus system allows the robot to maintain the right distance between the head and the piece to be treated. Due to proprietary technology, we can offer a number of customized configurations of the laser machines depending on the customers’ needs.

The OT-LAS laser machines feature:

One of the laser machine advantages is the possibility to carry out original and flawless processing with very low power consumption and low plant costs. High processing speed and extremely reduced manufacturing time give rise to decisive saving of resources. Furthermore, differently from the water-jet, the laser engraving and cutting machines for thermoformed materials do not generate waste materials, thus preventing the production of exceeding waste. Thanks to the laser cutting and engraving systems even costs related to disposal are eliminated, thus featuring amazingly easy changes of the cutting shapes with very low power costs.

The OT-LAS laser machines can lead to:

Do you have any more questions? Learn more about Ot-las laser systems.

To find out more we recommend you take a look at the related articles and explore the topic further.

The CO2 laser is particularly recommended for 3D cutting finishing of thermoformed, printed or blown plastics, as it allows obtaining

The CO2 laser is particularly recommended for 3D cutting finishing of thermoformed, printed or blown plastics, as it allows obtaining

Call us to speak with one of our experts who will show you the solution that best meets your needs.

Service

Ph: (+39) 055 7760184

Email: service@otlas.it

Office

Ph: (+39) 055 7760183

Email: info@otlas.it

monday – friday

from 09.00 a.m. to 18.30 p.m.

Legal office

Via Baldanzese 17, 50041

Calenzano (FI)

Head office

Via Pantano 16/G, 50013

Campi Bisenzio (FI)

Offices

Via Cherzani 16/5, 50041

Calenzano (FI)

Company info

Laser solutions

©2025 Ot-las s.r.l. – Cod. Fisc e Reg Imp FI n. 04418930485 – P.Iva 04418930485 – REA FI: 448229 – Cap. Soc. € 154.621,14 i.v.s.