- Laser Machines

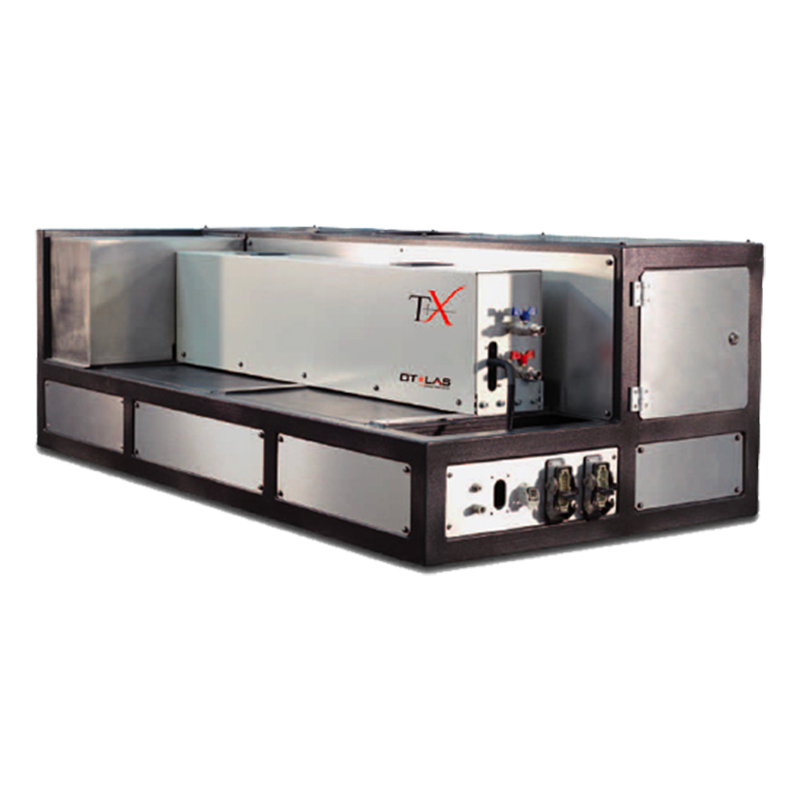

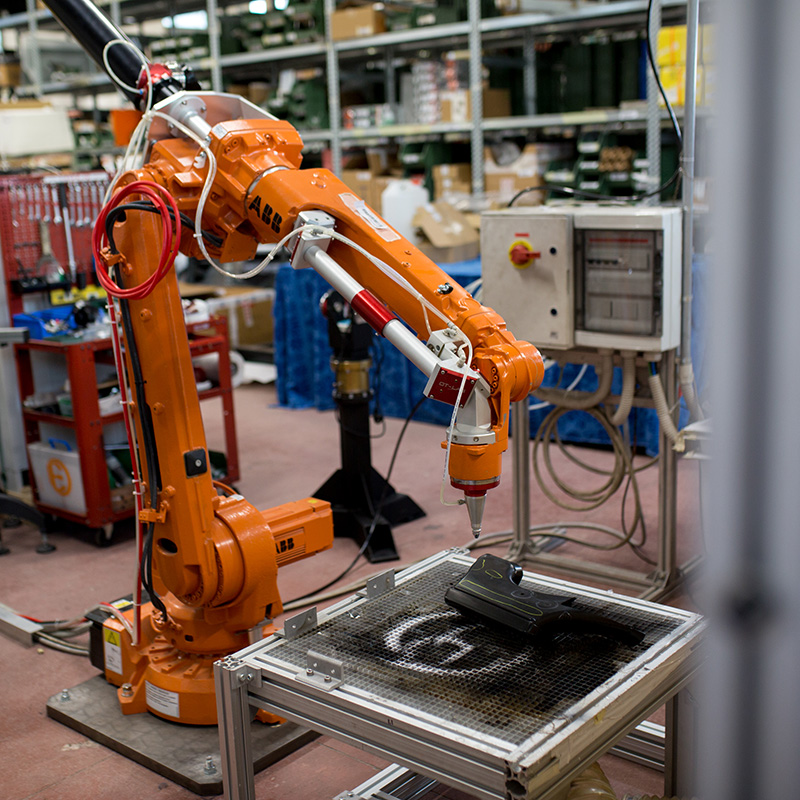

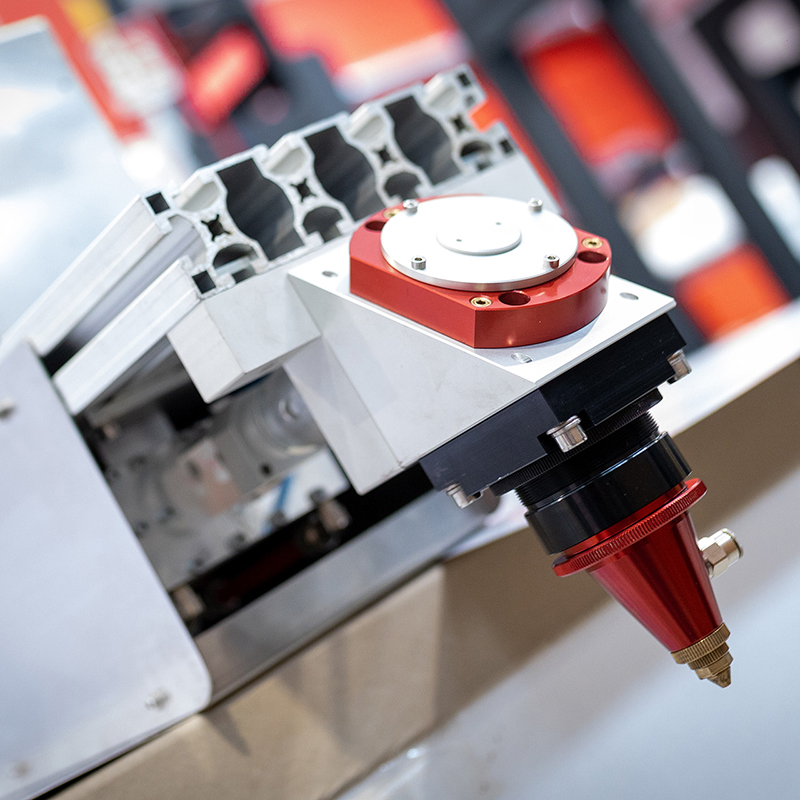

Customization of laser machines for special applications, tailor-made configurations and integration into the manufacturing cycle.

Our laser systems are ideal to accurately cut insoles and related excavations.

Laser machines for high-precision microperforation of soundproof panels made of wood, plastic and other materials.

- Materials

- Sectors

- Company

- Blog

- Contacts

- Laser Machines

Customization of laser machines for special applications, tailor-made configurations and integration into the manufacturing cycle.

Our laser systems are ideal to accurately cut insoles and related excavations.

Laser machines for high-precision microperforation of soundproof panels made of wood, plastic and other materials.

- Materials

- Sectors

- Company

- Blog

- Contacts