Leather laser treatment: zero waste, maximum customisation

Leather laser treatment is an increasingly used technique in the creation of products for the fashion, automotive and interior design

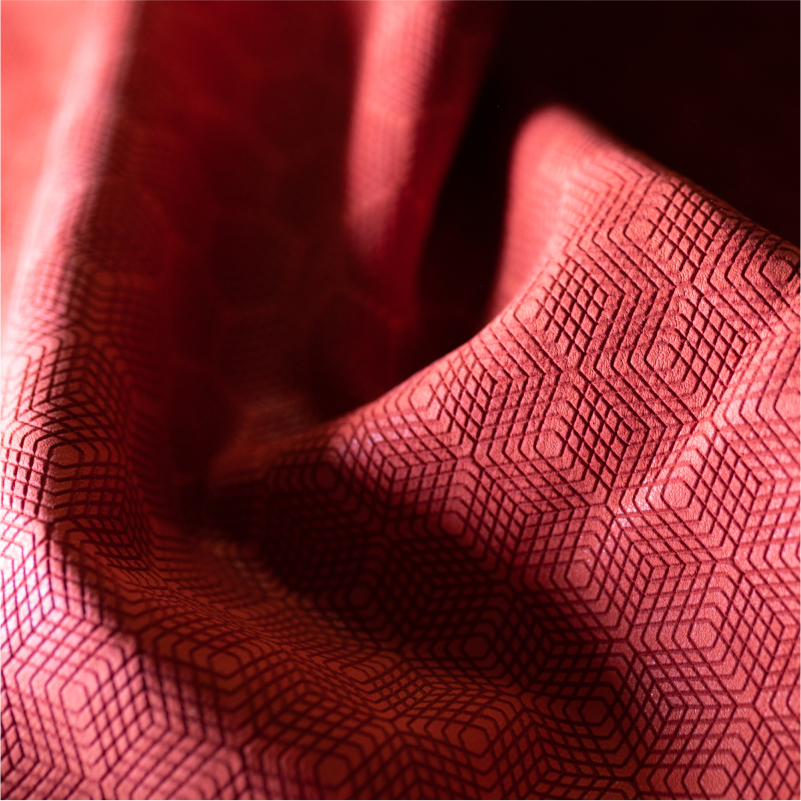

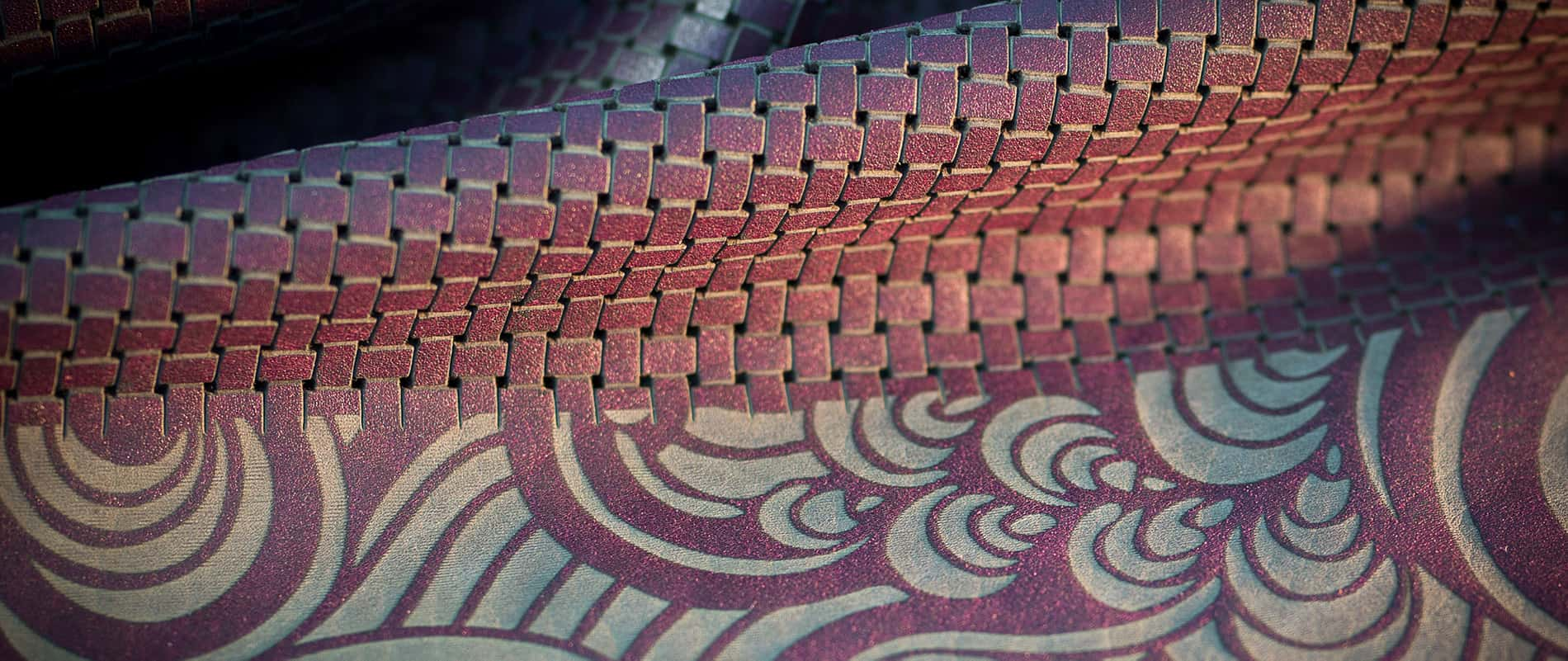

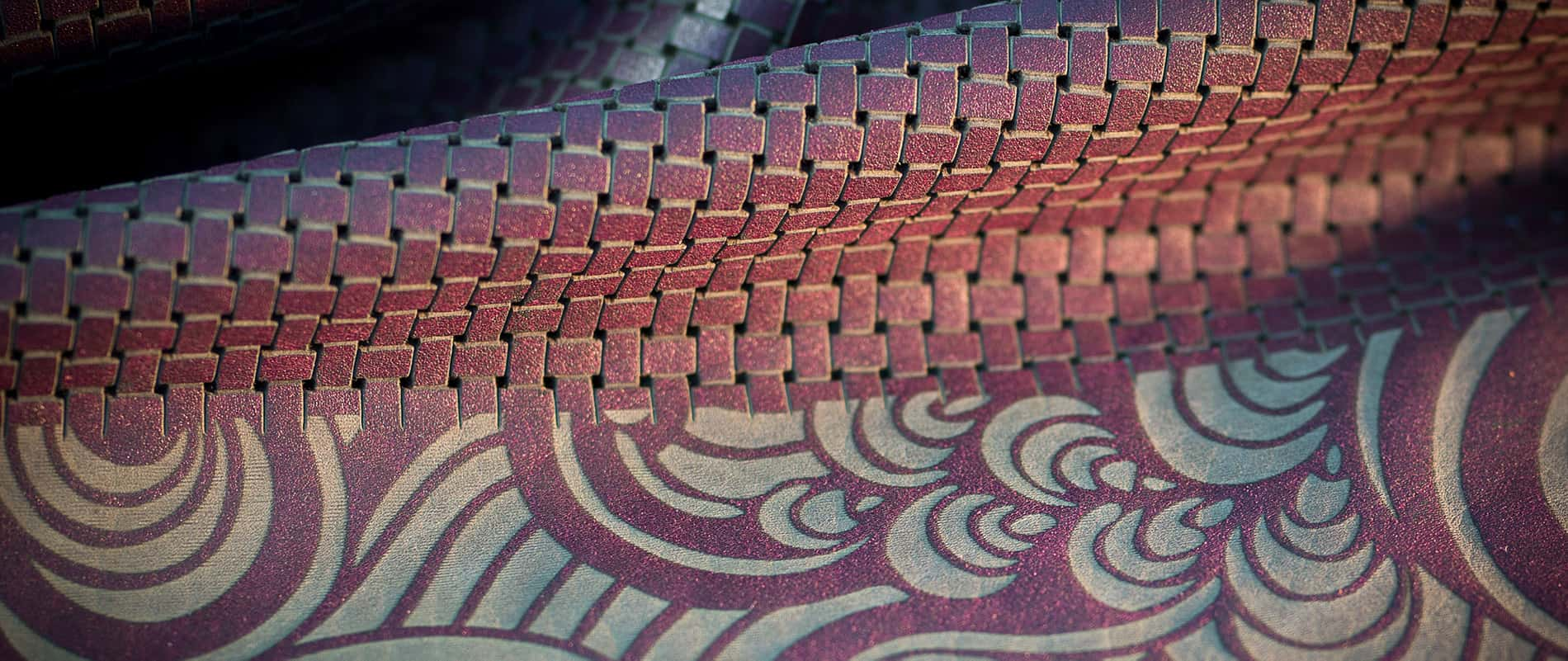

Leather is a noble material, able to inspire charm and sophistication. That is the reason why it is widely used in a number of sectors, in both its natural version and its green and synthetic alternative. From the fashion world and interior design, up to the automotive sector, the leather cutting and finishing represent key treatments. The specialist laser machines allowing precise cutting and neat edges as well as the possible realization of complex patterns in a short time involve a unique advantage. Due to our laser machines for leather, many items can be easily cut and marked such as bags, wallets, leather goods, uppers, whole pelts and many other accessories. Furthermore, there is not any risk of deformation thanks to the no contact – between machine and material – processing.

Laser technology is suitable for several kinds of leather, right by virtue of its delicate processing. Particular effects can be obtained with fur skins, as it is possible to carry out even complex bas-relief patterns.

In particular, the leather engraving and cutting machines can be used in case of:

Our laser systems for leather are directly designed and developed by us to properly cut, mark and drill hides. Through the most cutting-edge technologies we are able to provide our customers with the highest performance and unlimited possibilities of use. Versatility of applications and high quality guarantee top-class finishing in both single pieces and mass production.

Here are some advantages of the OT-LAS laser machines:

First, laser processing does not require fixing the piece onto the processing table. Since there is no contact between machine and leather, nor any kind of pressure, we just have to position leather and laser-treat it. In addition, laser technology is the only one able to cut and engrave at the same time, thus considerably reducing processing time. The treatment is easy and fast and the perfection of the final result does not need any further processing or finishing. This is why a laser machine for leather is the most recommended solution in industrial manufacturing.

Do you have any more questions? Learn more about Ot-las laser systems.

To find out more we recommend you take a look at the related articles and explore the topic further.

Leather laser treatment is an increasingly used technique in the creation of products for the fashion, automotive and interior design

What role does the laser play in leather processing? What are the advantages in terms of power, time and cost

Do you know that the laser machines are especially recommended to cut and mark leather, even the most precious one?

Leather laser treatment is an increasingly used technique in the creation of products for the fashion, automotive and interior design

What role does the laser play in leather processing? What are the advantages in terms of power, time and cost

Do you know that the laser machines are especially recommended to cut and mark leather, even the most precious one?

Call us to speak with one of our experts who will show you the solution that best meets your needs.

Service

Ph: (+39) 055 7760184

Email: service@otlas.it

Office

Ph: (+39) 055 7760183

Email: info@otlas.it

monday – friday

from 09.00 a.m. to 18.30 p.m.

Legal office

Via Baldanzese 17, 50041

Calenzano (FI)

Head office

Via Pantano 16/G, 50013

Campi Bisenzio (FI)

Offices

Via Cherzani 16/5, 50041

Calenzano (FI)

Company info

Laser solutions

©2025 Ot-las s.r.l. – Cod. Fisc e Reg Imp FI n. 04418930485 – P.Iva 04418930485 – REA FI: 448229 – Cap. Soc. € 154.621,14 i.v.s.