Main benefits of laser for wood microperforation

Main benefits of laser for wood microperforation The micro-perforation of wood is an essential process in the interior design sector

Customization of laser machines for special applications, tailor-made configurations and integration into the manufacturing cycle.

Our laser systems are ideal to accurately cut insoles and related excavations.

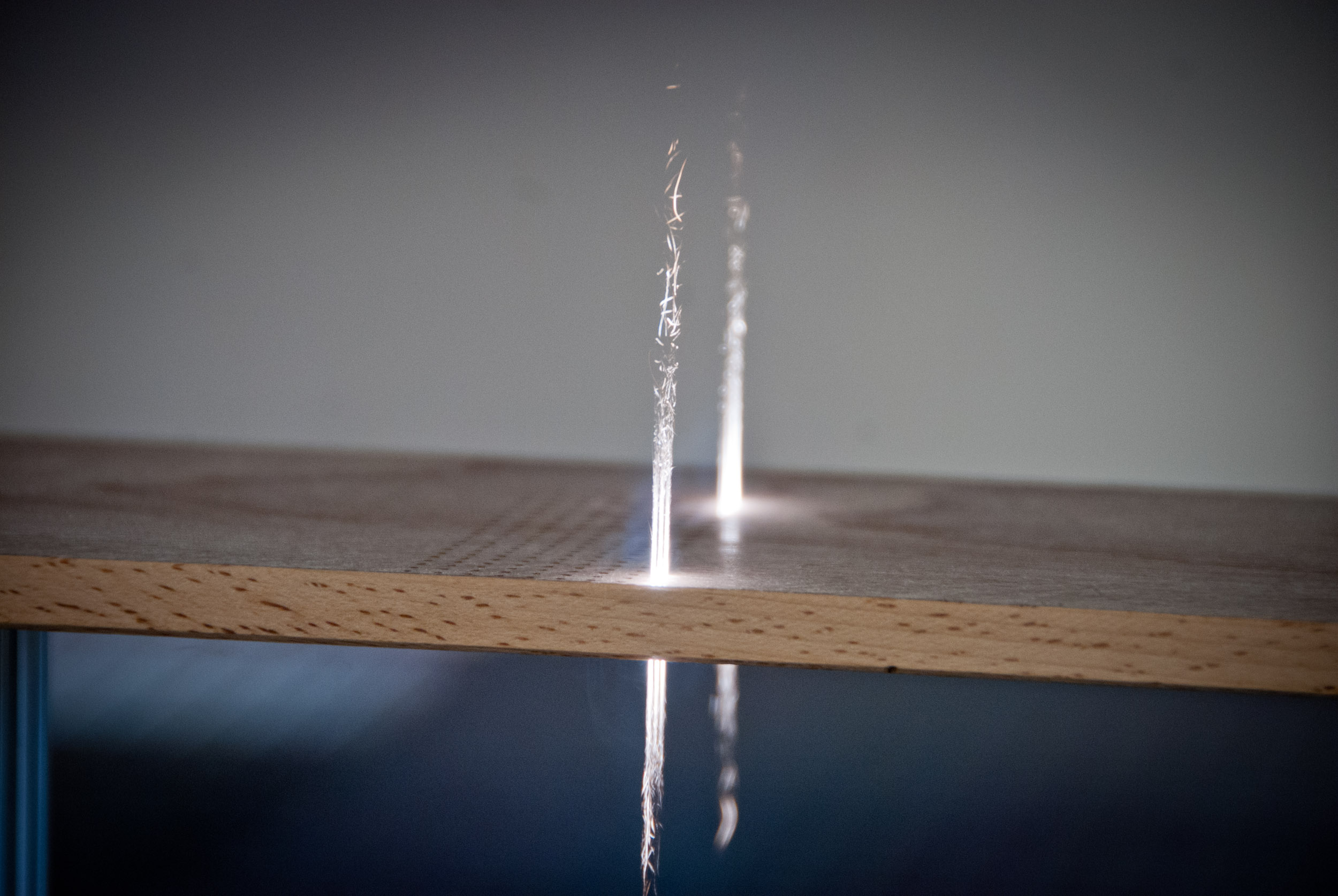

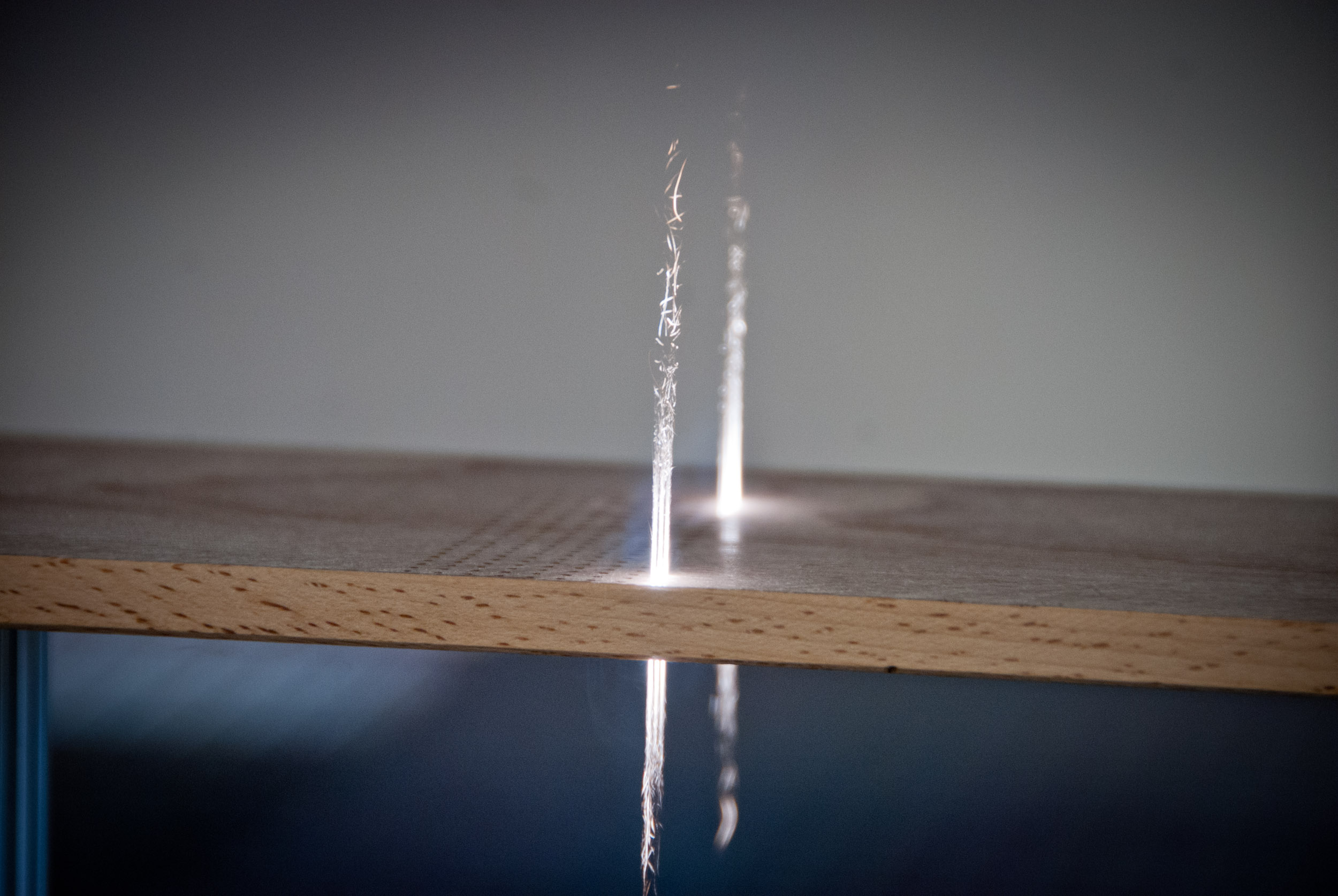

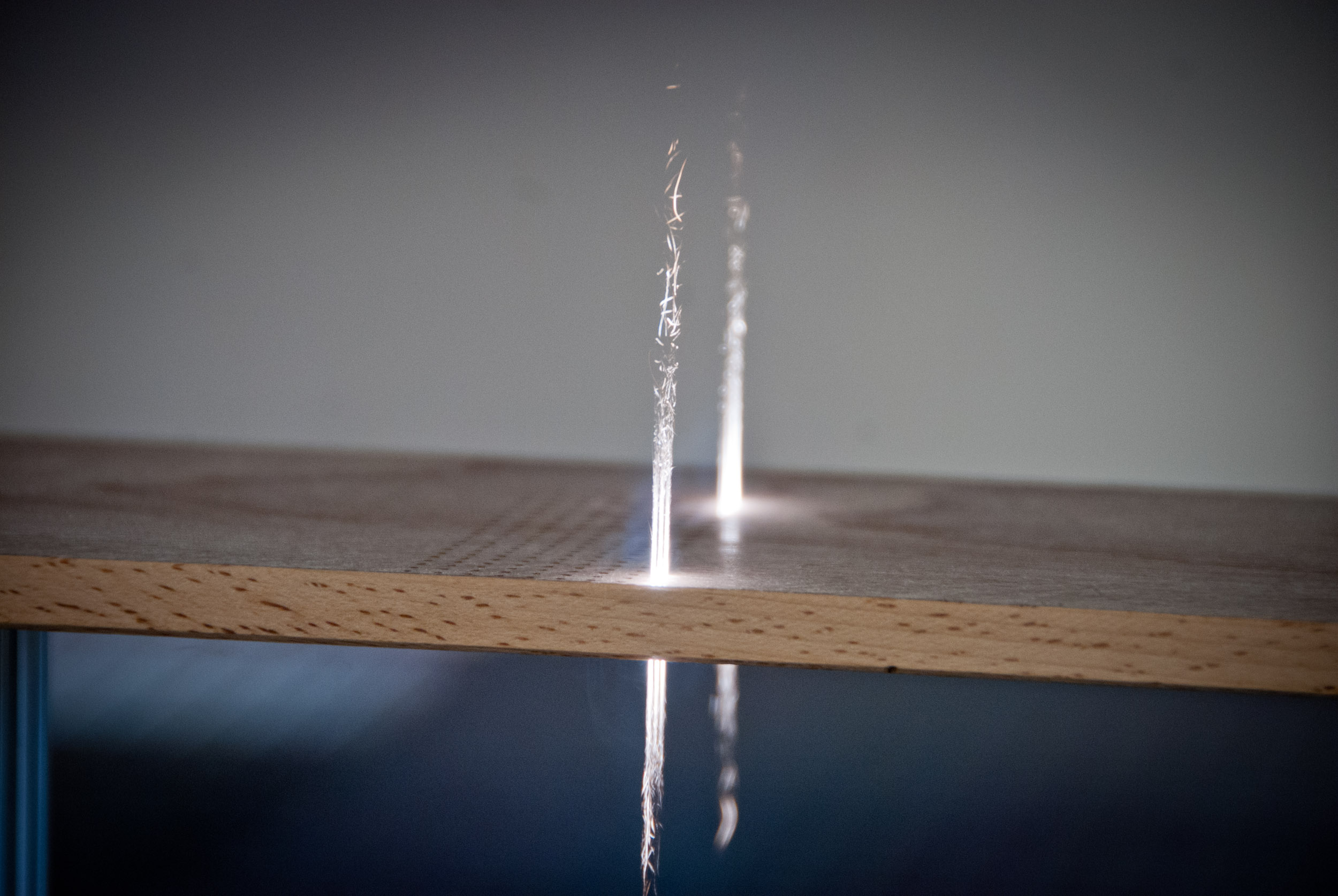

Laser machines for high-precision microperforation of soundproof panels made of wood, plastic and other materials.

Customization of laser machines for special applications, tailor-made configurations and integration into the manufacturing cycle.

Our laser systems are ideal to accurately cut insoles and related excavations.

Laser machines for high-precision microperforation of soundproof panels made of wood, plastic and other materials.

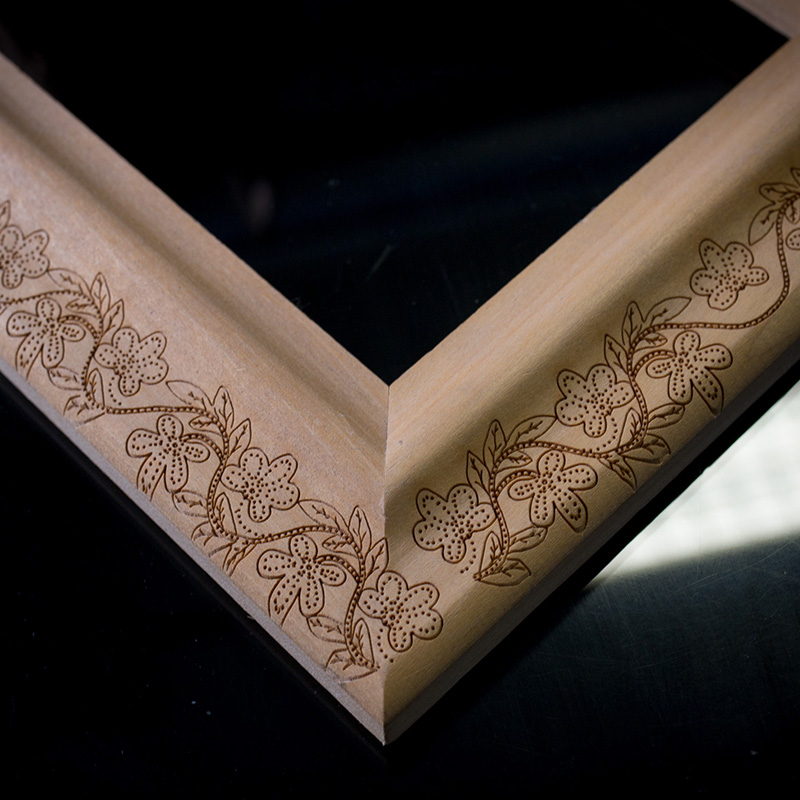

OT-LAS designs and develops laser machines and systems for engraving and cutting of wood, specifically devised to carry out exclusive and perfectly finished creations. Wood processing through laser machines allows carrying out complex bas-reliefs, cutting and engraving with the utmost simplicity and in a very short time.

There are a number of possible customizations and the result is always accurate and refined. In addition, the laser is a clean and environment-friendly technology, that requires a minimum use of power resources. The OT-LAS laser machines deliver performance excellence for any kind of processing, in favor of productivity and safeguard of the environment.

The applications related to the laser machines for wood are virtually endless. In handicraft too, laser processing equip wood with unique effects, reinterpreting past treatments that were carried out for instance by means of a pyrographer or a burin. The possibility of unique and sophisticated customizations makes laser processing an extraordinary resource in many sectors. From modeling items to gifts, up to interior design, for instance wood flooring, doors, furniture or even large tables and boards.

Thanks to the laser machines for cutting and engraving of wood, very complex objects, decorations, inlays and graphical elements can be created with a focus on the finest detail. The utmost precision of this kind of processing that does not require any finishing touch is coupled with extraordinary expressive freedom. Laser technology is in fact very versatile and lends itself to be combined with other types of processing to reach unique solutions. In addition, the only residue resulting from laser processing of wood is a minimum quantity of fumes that, in case of natural wood, are not polluting at all.

The laser cutting and engraving machines are suitable for any kind of wood, also including fine wood, provided that adequate setting of power and speed is guaranteed. The final result is always accurate with neat angles and never-frayed edges.

The recommended types of wood for laser processing include:

The laser machines for engraving and cutting of wood are not all the same. Our systems are designed and manufactured in-house starting from excellence components. Thanks to our departments’ expertise, we provide state-of-the-art solutions that are unique in terms of performance and customization. Dealing directly with the machine assembly, we can also offer bespoke configurations for special needs of our customers.

Here are some advantages of the OT-LAS laser machines:

The OT-LAS laser machines aim at the minimum impact on the environment. In fact, using the laser requires limited quantities of power for starting the machine. Differently from mechanical processing, the laser is more accurate and rapid in carrying out even very small details. This is the reason why using laser machines for wood engraving and cutting is a decidedly environment-friendly and sustainable choice:

Do you have any more questions? Learn more about Ot-las laser systems.

To find out more we recommend you take a look at the related articles and explore the topic further.

Main benefits of laser for wood microperforation The micro-perforation of wood is an essential process in the interior design sector

In the interior design world, micro drilling of laminates so as to reduce noise in crowded spaces is an increasingly

When a laser cutting becomes similar to a work of art, marquetry and woodwork with laser allows to reach very

Main benefits of laser for wood microperforation The micro-perforation of wood is an essential process in the interior design sector

In the interior design world, micro drilling of laminates so as to reduce noise in crowded spaces is an increasingly

When a laser cutting becomes similar to a work of art, marquetry and woodwork with laser allows to reach very

Call us to speak with one of our experts who will show you the solution that best meets your needs.

Service

Ph: (+39) 055 7760184

Email: service@otlas.it

Office

Ph: (+39) 055 7760183

Email: info@otlas.it

monday – friday

from 09.00 a.m. to 18.30 p.m.

Legal office

Via Baldanzese 17, 50041

Calenzano (FI)

Head office

Via Pantano 16/G, 50013

Campi Bisenzio (FI)

Offices

Via Cherzani 16/5, 50041

Calenzano (FI)

Company info

Soluzioni laser

©2023 Ot-las s.r.l. – Cod. Fisc e Reg Imp FI n. 04418930485 – P.Iva 04418930485 – REA FI: 448229 – Cap. Soc. € 154.621,14 i.v.s.