Main benefits of laser for wood microperforation

The micro-perforation of wood is an essential process in the interior design sector and in particular in the production of sound-absorbing panels. Thanks to the CO2 laser and the galvanometric heads, the machining quality has achieved excellent results compared to the use of traditional technologies. We see in detail the advantages of laser micro-drilling compared to punching machines in terms of quality, consumption, production time and operational flexibility.

Laser for micro-perforation of wooden panels: why it is convenient

The latest generation of CO2 laser micro-drilling machines are equipped with galvanometric scanning heads with very high precision. The microperforation process is guided through the handling of the scanning head, which combines control and flexibility. This allows extreme versatility in processing combined with high-profile performance compared to traditional processing. In particular, the CO2 laser has quickly established itself in companies that operate in the production of high-end furniture and coatings for acoustic comfort. Here are all the advantages that this technology guarantees:

Unmatched quality in processing

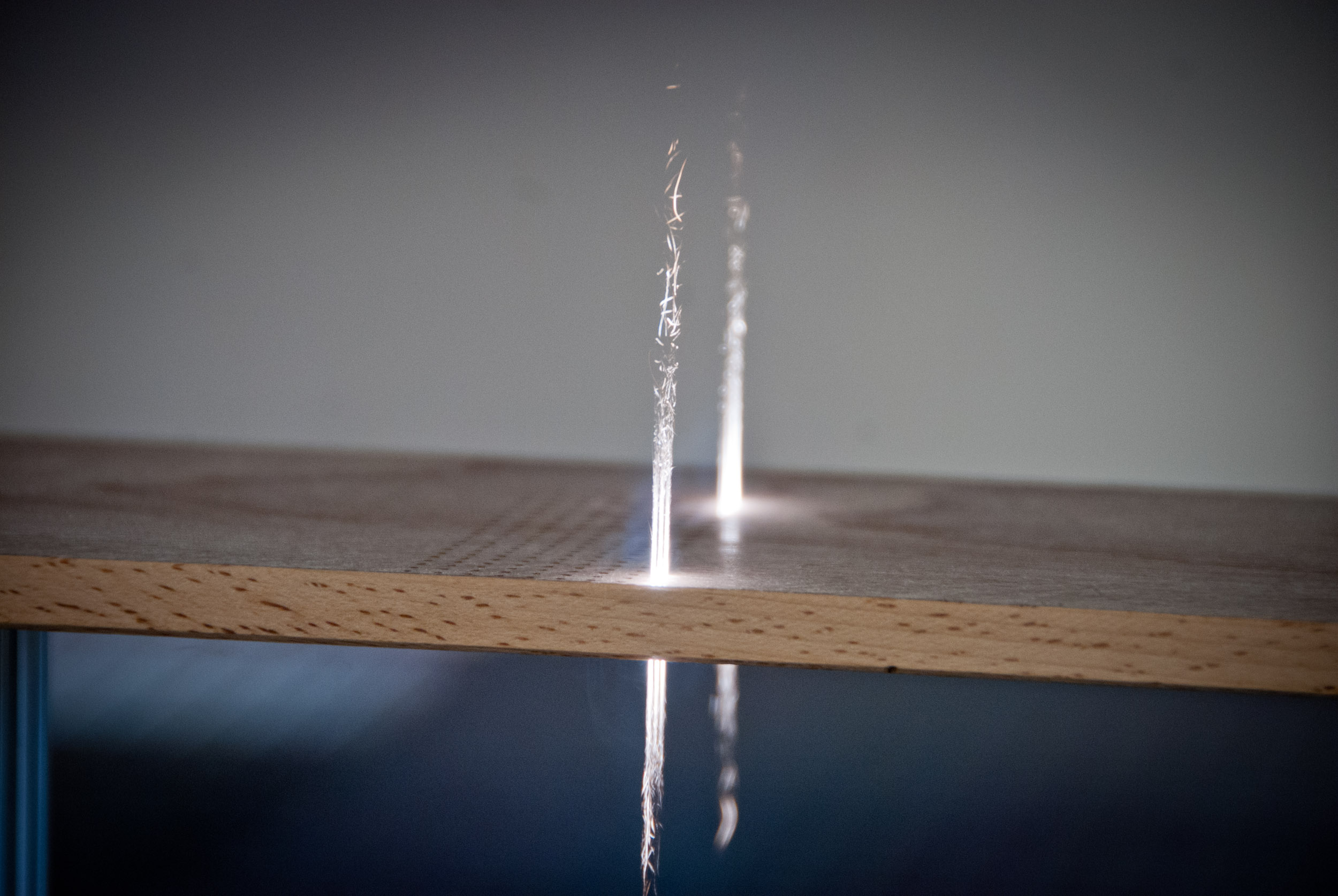

CO2 laser systems allow microperforation on wood with unparalleled precision. The laser technology allows the energy to be concentrated in a small spot, allowing punctures on the sound-absorbing panels with precision of the order of the tenth of a millimeter. The extreme precision translates into clean and burr-free edges of the micro-holes produced, ensuring an almost invisible finish for the benefit of both functionality and aesthetics. The result is far superior to that obtained with punching machines, which make more imperfect holes and with a greater risk of compromising the material.

Reduced consumption and sustainability

Another crucial element to consider is the energy sustainability offered by the combination of CO2 lasers and galvanometric heads. Unlike punch presses, which often require considerable amounts of energy, the CO2 laser stands out for its low consumption. This not only results in a lower environmental impact, but also in significant savings for the company on long-term operating costs.

The increased energy efficiency thus confers an essential competitive advantage, in perfect accordance with the need to reduce the consumption of resources. For this reason, combined with the reduction of material waste due to the precision of the processing, the laser is rightly a green technology for Industry 4.0.

Operational flexibility and competitiveness

Operational flexibility is the third key parameter that has contributed to the success of the CO2 laser in wood micro-perforation. Thanks to the possibility to vary the size of the holes, the distance between them and the spatial distribution in the panel, the galvanometric heads offer the possibility to choose any type of drilling. Their ability to move quickly, keeping the quality intact, allows a huge versatility and reduced production time.

Increased attention to the healthiness of the rooms has increased the demand for solutions for acoustic comfort. Both in the workplace and in living spaces, it is now essential to introduce furnishings and coverings that take this aspect into account. The combination of flexibility, speed and precision of the CO2 laser allows companies to respond promptly to new needs.

Personalization and creative freedom

It is well known that in the field of interior design customization is an essential factor. The CO2 laser with galvanometric head can perform an inexhaustible range of processes, allowing companies to customize the sound-absorbing panels according to style and creativity.

The galvanometric heads allow to realize even complex patterns and compositions, with a quick adaptability to the specific needs of the customer. In addition, unlike microperforation with punching machines, laser microperforation can be practically imperceptible from an aesthetic point of view, with a clear advantage for the design.

OT-LAS laser systems for high performance wood microperforation

Unmatched quality, energy sustainability and flexibility make laser the ideal technology for micro-perforation of wood. To meet every need for micro-perforation, OT-LAS designs and manufactures high performance CO2 laser systems and entirely Made in Italy. The extreme precision of the optical system and the innovative technology guarantee the high quality of the finished products, while optimizing production processes. The OT-LAS team is always available to provide advice and dedicated assistance or to customize the systems with customized configurations.

Discover our CX Microperforation laser machine or contact us for information.