Maximum Power

1500 W

Maximum Area

700×700 mm

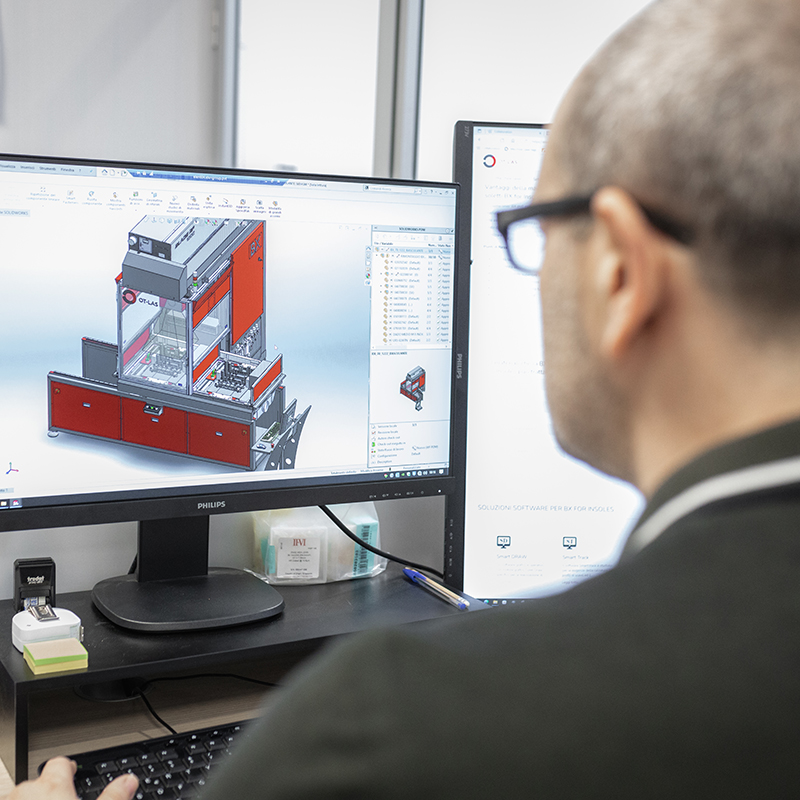

BX for Insoles, the laser marking system for footwear

BX for Insoles is the perfect solution for excavation of insoles and eyelets.

The excavation profiles and eyelet cutting are projected to insoles, opportunely positioned on valid reference systems for each shoe size and shape.

Advantages of the BX for Insoles laser machine

The BX for Insoles laser system is equipped with a system of tilting templates to allow perpendicular cutting of eyelets on insoles. Furthermore, the machine is equipped with double station to streamline the production cycle.

The BX for Insoles highlights:

- Laser power up to 1500 Watt.

- New high-performance optical head.

- Peak power higher than 2000 Watt.

- Easy and fast processing of excavation profiles.

- Automatic development of sizes.

- Import of DXF files.

Technical Characteristics

Processing is made using the SmartTrim software specifically designed for the needs of each shoe with a power up to 1500 Watt: working insoles has never been so fast and clean.

| Blade RF | 555 | 775 | 888 | 1222 | 1555 |

| Rated power (W) | 550 | 750 | 850 | 1200 | 1500 |

| Electric consumption (kW) | 9 | 10 | 12 | 13 | 22 |

| Useful marking area (mm) | 600×600 – Rated Spot 0.6 mm 700×700 – Rated Spot 0.35 mm | ||||

| Galvanometric polar scanning optical head | Optical aperture 35mm Optical aperture 70mm | ||||

| Automatic plan | Double tilting station for loading and unloading | ||||

| Electric Power Supply (VAC) | machine: 400 3F+T ±10% – 50 Hz refrigerator: 400 3F+T ±10% – 50 Hz | ||||

Accessories and hardware for BX for Insoles

H70 High-definition scanning head

High-definition galvanometric scanning system internally developed by OT-LAS with 70mm optical aperture.

H35 scanning head

Galvanometric scanning system internally developed by OT-LAS with 35mm optical aperture.

Double-station insole table

Automatic table for insoles with tilting system.

Single-station insole table

Insole table with tilting system.

Software for BX for Insoles

A graphic and operating software with specific Corel Draw graphic engine for the realization of files and for the entire system functioning. For each work, it is possible to assign geometric parameters, processing parameters and set any drawing repetitions or compositions, in case the system is equipped with automatic table.

A machine management software that can open various formats such as PLT, BMP, etc. Engraving allows setting speed and power parameters, and creating processing lists.

The SmartTrack software is designed to carry out insole excavation. Excavation profiles and cutting of eyelets are projected to insoles, opportunely positioned on valid reference systems for each size and shape.