Maximum Power

1500 W

Maximum Area

700×1600 mm

Maximum Power

1500 W

Maximum Area

700×700 mm

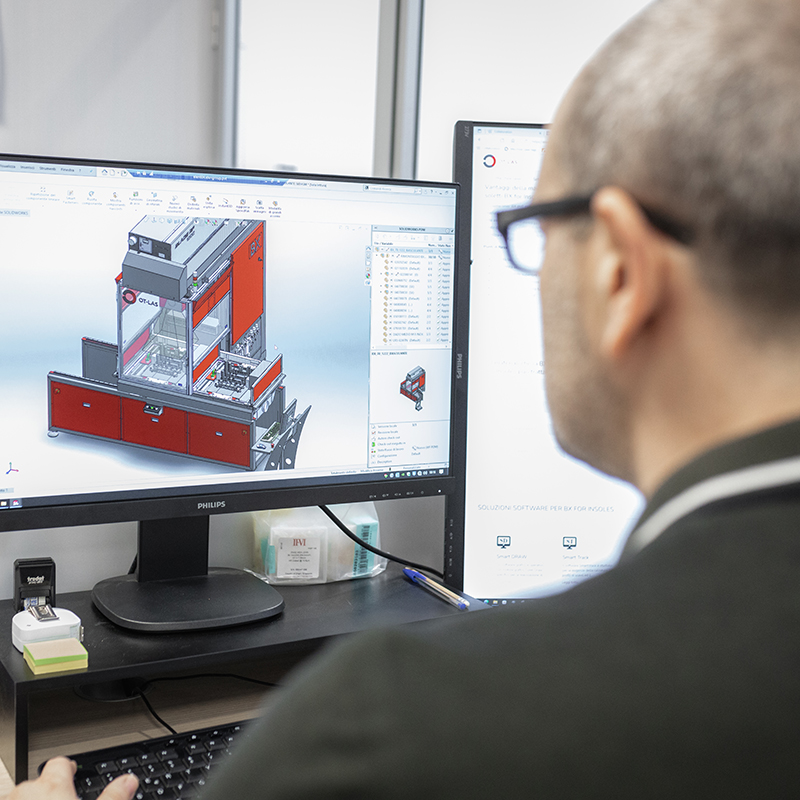

BX, the ideal solution for medium and large formats

BX is the most flexible laser solution for cutting and marking. The BX system combines high power of the laser source with ultra-high-definition optical head, designed for extremely precise processing on medium to large working areas.

BX can process the following materials:

- Leather

- Insoles

- Glass

- Marble

- Wood

- Textile

Advantages of the BX laser machine

With its technical characteristics and high performances, the BX laser system combines efficiency and reliability.

BX is the ideal laser machine for cutting and marking leather and footwear components. It is also suitable for wood, marble and pieces of textile.

The BX highlights:

- Equipped with graphic and operating software and Corel Draw graphic engine.

- It combines excellent performances and high flexibility.

- Available with 35mm or 70mm galvanometric scanning head.

- In the “fly marking” mode, processing can be performed on wider areas than the single area.

Technical characteristics

BX can have a 35mm or 70mm (high definition) scanning head, based on the production needs. The presence of automatic or manual work plans, specific to the application, allows processing on wider areas than the single area.

| Blade RF | 333 | 555 | 777 | 888 | 1222 | 1555 |

| Rated power (W) | 350 | 550 | 750 | 850 | 1200 | 1500 |

| Electric consumption (kW) | 9 | 10 | 12 | 13 | 22 | 23 |

| Single useful area (mm) | from 250×250 to 600×600 – Rated Spot from 0.25mm to 0.6mm | |||||

| Galvanometric polar scanning optical headgalvanometrica | Optical aperture 35mm Optical aperture 70mm | |||||

| Y-axis automatic plan | Stroke: 900mm Step movement continuous mov. (“fly marking”) | |||||

| Useful marking area (mm) | 250×1150 with single area 250×250 (H35) 600×1500 with single area 600×600 (H35) 500×1400 with single area 500×500 (H70) 700×1600 with single area 700×700 (H70) | |||||

| Electric Power Supply (VAC) | machine: 400 3F+T ±10% 50 H refrigerator: 400 3F+T ±10% 50 Hz | |||||

| Blade RF | 333 | 555 | 777 | 888 | 1222 | 1555 |

| Rated power (W) | 350 | 550 | 750 | 850 | 1200 | 1500 |

| Electric consumption (kW) | 9 | 10 | 12 | 13 | 22 | 23 |

| Useful marking area (mm) | from 250×250 to 600×600 – Rated Spot from 0.25mm to 0.6mm | |||||

| Galvanometric polar scanning optical head | Optical aperture 35mm Optical aperture 70mm | |||||

| Alimentazione elettrica (VAC) | macchina: 400 3F+T ±10% – 50 Hz refrigeratore: 400 3F+T ±10% – 50 Hz | |||||

| Blade RF | 333 | 555 | 777 | 888 | 1222 | 1555 |

| Rated power (W) | 350 | 550 | 750 | 850 | 1200 | 1500 |

| Electric consumption (kW) | 9 | 10 | 12 | 13 | 22 | 23 |

| Single useful area (mm) | from 250×250 to 600×600 – Rated Spot from 0.25mm to 0.6mm from 500×500 to 700×700 – Rated Spot from 0.25 mm to 0.35mm | |||||

| Galvanometric polar scanning optical headgalvanometrica | Optical aperture 35mm Optical aperture 70mm | |||||

| Y-axis automatic plan | Stroke: 900mm Step movement continuous mov. (“fly marking”) | |||||

| Useful marking area (mm) | 250×1150 with single area 250×250 (H35) 600×1500 with single area 600×600 (H35) 500×1400 with single area 500×500 (H70) 700×1600 with single area 700×700 (H70) | |||||

| Electric Power Supply (VAC) | machine: 400 3F+T ±10% 50 H refrigerator: 400 3F+T ±10% 50 Hz | |||||

| Blade RF | 333 | 555 | 777 | 888 | 1222 | 1555 |

| Rated power (W) | 350 | 550 | 750 | 850 | 1200 | 1500 |

| Electric consumption (kW) | 9 | 10 | 12 | 13 | 22 | 23 |

| Useful marking area (mm) | from 250×250 to 600×600 – Rated Spot from 0.25mm to 0.6mm from 500×500 to 700×700 – Rated Spot from 0.25 mm to 0.35mm | |||||

| Galvanometric polar scanning optical head | Optical aperture 35mm Optical aperture 70mm | |||||

| Alimentazione elettrica (VAC) | macchina: 400 3F+T ±10% – 50 Hz refrigeratore: 400 3F+T ±10% – 50 Hz | |||||

Accessories and hardware for BX

H70 High-definition scanning head

High-definition galvanometric scanning system internally developed by OT-LAS with 70mm optical aperture.

H35 scanning head

Galvanometric scanning system internally developed by OT-LAS with 35mm optical aperture.

Automatic moving table

Automatic moving table with high precision movement and absolute encoder, for continuous or stepped processing.

Conveyor

System for continuous processing, suitable for different process types.

Manual moving table

Manual-handling moving table.

Vision system

The vision system allows recognizing the shapes of objects positioned on the working table, in combination with Smart Trim software.

Software for BX

A graphic and operating software with specific Corel Draw graphic engine for the realization of files and for the entire system functioning. For each work, it is possible to assign geometric parameters, processing parameters and set any drawing repetitions or compositions, in case the system is equipped with automatic table.

A machine management software that can open various formats such as PLT, BMP, etc. Engraving allows setting speed and power parameters, and creating processing lists.

Software for the recognition of plan surfaces edges. Due to this application, laser processing will be optimized based on the surface requested. Smart Trim is combined with the vision system.