Which materials can be marked by laser and why it is convenient

Laser marking systems offer an advanced and versatile technology that has innovated the manufacturing industry. The laser allows you to engrave or mark materials with more than a millimeter precision and is much more efficient and sustainable than other marking techniques. It is no coincidence that laser machines are now widely used in various industrial sectors, including fashion, automotive, interior design, objects and the food industry. But what materials can be marked by laser and why is it so convenient? Here are some applications for which this technology is indicated and the reasons that have pushed many companies to adopt it.

Materials suitable for laser marking

Laser marking technology can be used to engrave or mark a wide range of materials. However, it must be taken into account that each material requires specific power and speed parameters to obtain an optimal result. Materials that can be marked or engraved with CO2 lasers include:

Leather

Organic materials, such as leather, can be marked by laser for decorative purposes, to apply information such as logos or serial numbers, or to create exclusive footwear and accessories. In addition to natural leathers, synthetic and microfiber leathers can also be marked by laser.

Fabric

The CO2 laser lends itself to the processing of many fabrics, such as denim, cotton, linen, silk, viscose but also polyester, polyamide and technical fabrics. Laser marking can take place on pieces or directly on rolls, as in the case of the OT-LAS laser machine called MX.

Glass

Glass is another material that can be perfectly engraved with the laser. This technique is for example used in the production of tempered glass to create particular decorative effects, trademarks or traceability codes.

Ceramic

Laser marking on ceramics is used in areas such as the production of tiles, design ceramics, tableware and objects. The precision and versatility of laser marking guarantees high-profile, original and well-defined results even in the case of complex decorations.

Marble

The CO2 laser allows you to engrave marble and other natural stones to create prestigious interior design elements or craft creations. In a few minutes you can get unique decorations, patterns and geometries that enhance the beauty of these raw materials.

Wood

The wood can also be laser marked for decorative and furnishing purposes. The CO2 laser is effective on solid wood, teak, plywood, oak, cork, maple, bamboo and other types of wood. Laser marking can be used to customize furniture, coatings and art objects. In addition, the laser is more and more used for micro-perforation of sound-absorbing MDF panels. This technology, in fact, guarantees maximum flexibility and high quality.

Plastic

Plastics can be marked by laser to obtain design objects or to identify different elements of a set. Laser marking on plastics is particularly advantageous because it does not involve mechanical alteration of the material, protecting its integrity and obtaining clean edges.

Paper

In the paper industry, the laser is particularly appreciated because it allows the marking of smooth and corrugated board, coated and uncoated paper, without risk of burn. A decisive advantage to avoid material waste even in the most delicate processes.

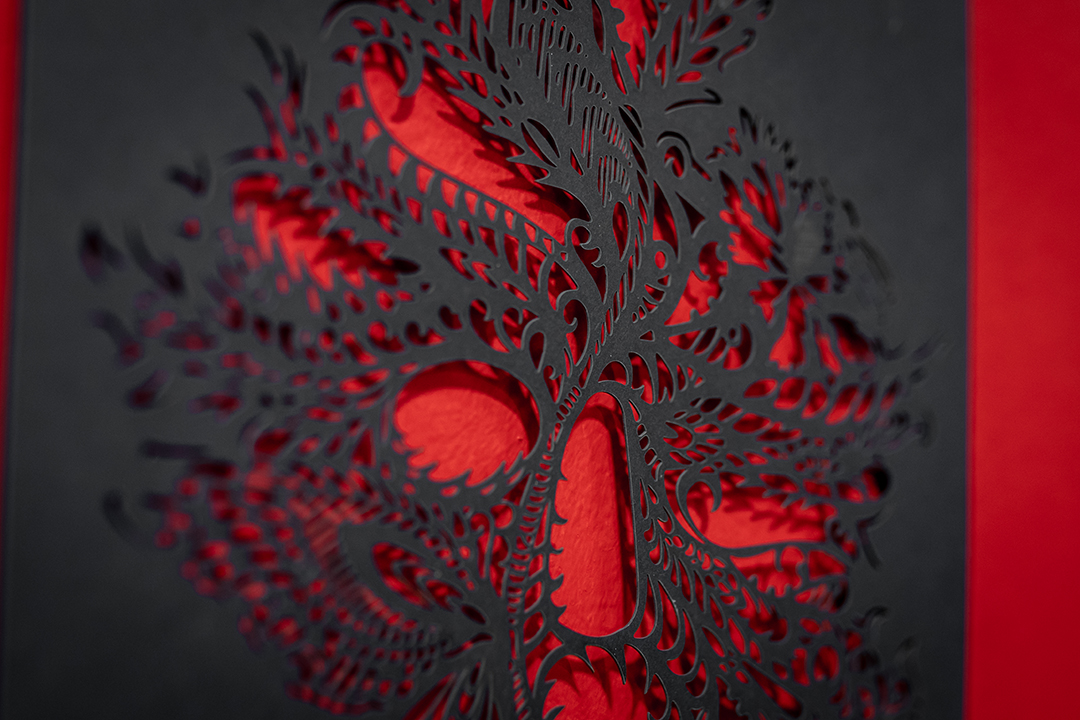

Acrylic

Laser marking of acrylic materials is often used to obtain advertising materials, signs and furnishing accessories with decorations of all shape and geometry. The flexibility of this tool allows you to satisfy every request for uniqueness, proving to be ideal for branding.

Thermoformed

In the production of industrial moulds, laser marking allows to obtain excellent finishes on materials such as thermoformed, ABS and composite materials. In addition to the very high quality of processing, the typical laser speed reduces production time and costs to a minimum.

Food

The possibility of marking food without compromising its organoleptic characteristics has made the laser a valuable technology also for the food industry. From the logos of the manufacturing companies to the indications of the expiration date up to the codes for traceability, the laser allows to engrave indelibly and safely any useful information.

Why laser marking is convenient for companies

Compared to traditional techniques, laser marking offers numerous advantages for companies. Here are some of the reasons why this technology is so convenient:

High precision processing

Laser marking offers an extraordinary level of precision. It can be used to create tiny details, small texts, complex and subtle graphics, ensuring an accurate and elegant result.

Durability and resistance

Laser marking is permanent and resistant to wear, abrasion and exposure to weathering. This makes it ideal for applications that require long-lasting labelling.

Reduction of production costs

The automation provided by laser machines, the speed of the galvanometric technology and the absence of finishing significantly reduce operating time and costs. In addition, unlike other marking techniques, such as inkjet marking or screen printing, laser marking does not require the use of consumables such as ink or screens.

Maximum efficiency and speed

Laser marking is extremely fast and efficient. It can be automated for high production applications, reducing machining time and increasing productivity. Its flexibility and reproducibility without loss from a qualitative point of view, make it ideal for both large productions and prototyping or limited edition.

Versatility in applications

Laser processing can be carried out on a wide range of materials, as we saw earlier. In addition, the effects that can be achieved are potentially endless and allow an exceptional level of customization.

Environmentally friendly technology

One of the most important advantages of laser marking is that it is an environmentally friendly process, as it does not produce toxic or polluting waste. In addition, laser systems consume a limited amount of resources compared to other more energy-intensive technologies. The laser is therefore a sustainable choice for the industry, in line with the needs of environmentally friendly production.

Discover on the website all OT-LAS machines for laser marking or contact us to receive information.