How to integrate laser into the manufacturing cycle?

There is an increasing number of companies choosing to integrate laser into the manufacturing cycle, with a view to automating processes and treatments. This is due to the various advantages offered by laser machines on operational, economic and safety levels. Flexibility of laser systems and the wide range of possible applications on natural and synthetic materials foster their integration into the manufacturing cycle while increasing efficiency and innovation. What aspects need to be considered to best adjust this technology to the workflow?

Why integrate laser into the company manufacturing

Before assessing the purchase of a laser machine, it is important to understand what the advantages of laser for the company manufacturing are. Within the framework of industry 4.0, the automation of manufacturing processes plays a key role and allows optimizing quality, time and operating costs. Laser machines perfectly meet these needs, since they allow engraving and marking materials with the utmost accuracy and in a very short time.

Furthermore, laser offers customizing possibilities that were once inconceivable, with limited costs and reduced energy consumption compared with the traditional methods. Lastly, laser machines create a safer working environment for the operators, and an eco-friendlier one. Since they work without contact, without any chemical product or material wastes, environmental impact is considerably reduced. To sum up, integrating laser into the production cycle allows getting:

- Production speed

- Highest processing quality

- Cost saving

- Green processing

- No material wastes

- No tool changes

- Reduction of machine downtime

- Maximum customization

- Production versatility

- Automation of manufacturing processes

What to take into account to integrate laser into the manufacturing cycle

Purchasing a laser system is an investment paid back by the economic and production advantages brought by innovation. It is important to previously take into account all indispensable aspects and needs regarding the integration into the manufacturing cycle, so as to avoid any purchase mistakes. These include:

Applications of the laser machine

The first aspect to be considered in the integration of a laser system into manufacturing is the application it will be designed for. CO2 laser is suitable for processing a wide range of materials, from the most natural ones, such as stone and leather, to the most synthetic ones, such as plastic and thermoformed. It is important to make sure that the laser machine chosen be suitable to mark and engrave the material used, in terms of type, quality and shape of pieces. Integration into the manufacturing should then take into consideration what aspects will be optimized, what processes will be automated and what systems will operate in combination with the new technology.

Free space in the production department

Secondly, but not less important, is assessing the area where the laser machine will be installed. Laser systems have different sizes based on the application and models on the market. For an effective result, it is essential to consider the entire space required by the machine and the ideal position based on the manufacturing needs. When space is limited, compact laser machines may be the right choice, provided the model selected guarantees the performance required.

Quality of the laser machine

One of the most common mistakes in the integration of a new technology into the company is focusing right on a low initial investment. Low cost often corresponds to a similarly low processing quality, in terms of accuracy, productivity, general performance and reliability over time. You’d better choose a high-quality laser system, with a cutting head that guarantees flawless accuracy even at increasing powers and speeds.

Quality of service and technical support

Other crucial aspects to be considered are the support guaranteed by the manufacturer for routine and extraordinary maintenance, and the customization possibilities. Most of all, when integrating laser into an existing manufacturing cycle, the machine customized configuration is a decisive advantage. This way, you will be sure to purchase a tailor-made machine based on your needs and perfectly meeting the purpose expected.

Operational flexibility and combined applications

In order to take advantage of all benefits offered by laser technology, it is advisable to previously consider what additional processing will be performed at the same time. Laser can be integrated into other systems to automate the operations and obtain complex treatments without changing tools. For this type of integration, it is important to check the compatibility of the laser system with any other combined system. This is also why the ideal solution is selecting a manufacturer that is open to customization and has proprietary software.

The advantages of choosing Ot-Las for company manufacturing

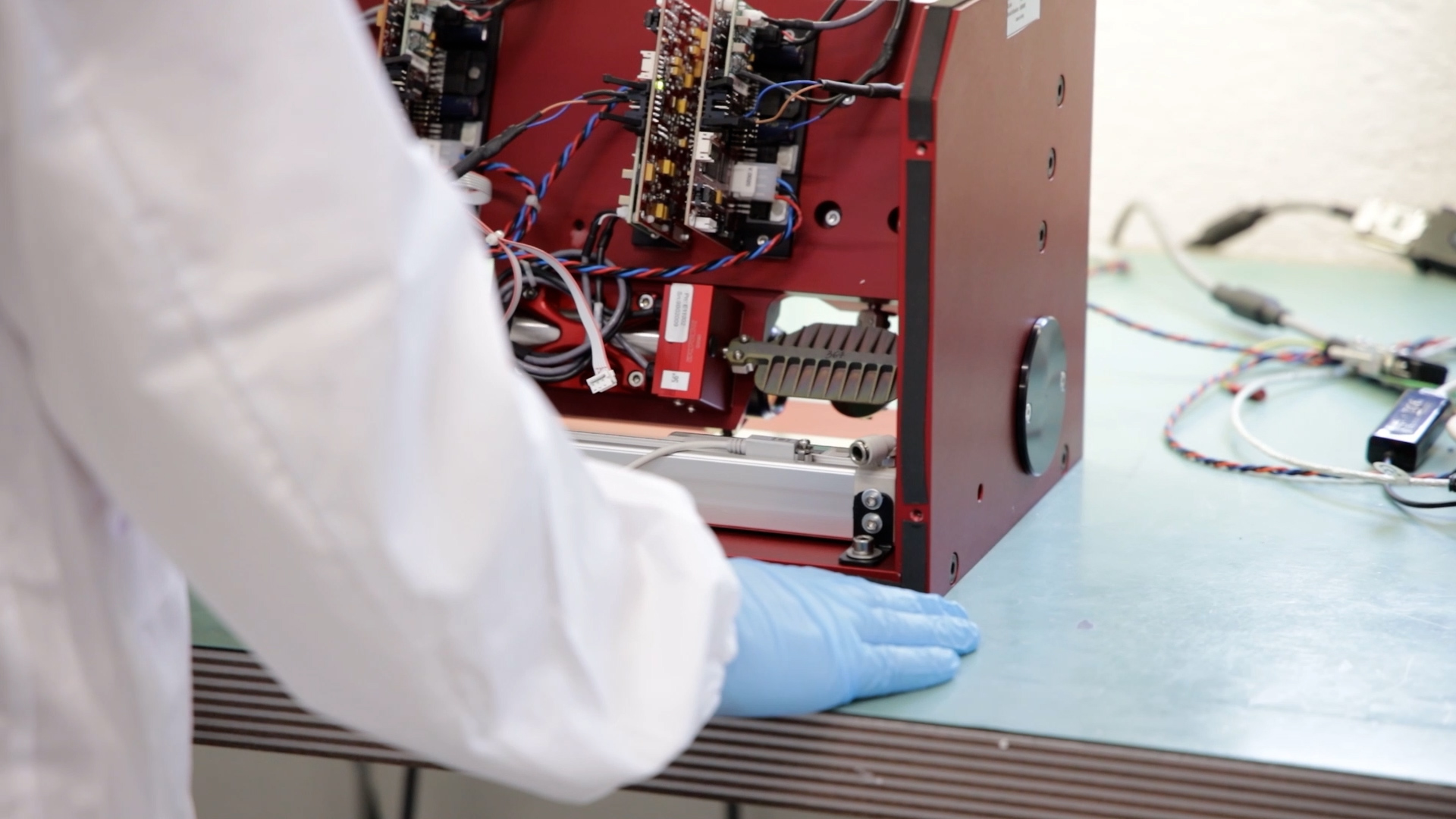

Since over 30 years, Ot-Las has designed and manufactured high-technology laser machines for engraving and marking with CO2 laser. Entirely made in Italy and customizable based on the manufacturing needs, the Ot-Las laser systems offer the highest processing quality at high speed and power performance. Proprietary software and technology allow guaranteeing reliability and operational flexibility, with ongoing and timely technical support.

Find out more about our laser machines for manufacturing or contact us for any further information.