Before purchasing a laser system, it is important to evaluate not only the performance but also the maintenance costs of the system, its durability and its management over time. These are aspects that directly affect machine reliability, costs to the company, and production continuity. A correct estimation of these aspects prevents counterproductive investments based only on the initial price.

Why maintenance is essential

A CO₂ laser system is a high-precision industrial machine, designed for repeatable and constant machining on various materials. Precisely for this reason it requires careful management over time. Compared to other technologies that allow for similar processing, the laser machine does not require as much maintenance or continuous interventions to replace wearable parts that wear out.

In any case, keeping the machine clean and carrying out regular checks, especially on the optics, guarantee stability and quality of the workmanship, reducing unwanted anomalies or performance losses.

The CO₂ laser source

The laser source represents the heart of the machine. High-quality radio frequency CO₂ laser sources are designed to ensure beam stability and performance continuity even over extended duty cycles. This reduces the need for corrective interventions, contributing to the good operational life of the system. The CO2 laser sources produced by El.En. group can be sealed-off or semi-sealed. Sealed-off sources are formed by a closed cavity inside which the gas tends to be exhausted after some time. When laser performance starts to decline, it means that the source must be replaced or regenerated, resulting in machine downtime with direct impacts on production. To address the disadvantages of maintenance, El.En. group has developed semi-sealed laser sources based on the innovative “Self-Refilling” technology. Through the six-monthly replacement of gas mixture (purchasable from OT-LAS) the performance of the laser source over time is guaranteed.

Operating conditions

The environment in which the machine operates also plays an important role. Powders, processing residues, and inadequate cleaning can accelerate component wear. Proper cleaning of the working area makes a concrete contribution to preserving laser performance over time.

Routine maintenance of a laser machine

Routine maintenance includes a series of control and cleaning operations that allow the system to be kept in optimal operating conditions. These are programmable activities that, in some cases, can be carried out directly by operators, provided they are adequately trained.

Major operations include cleaning surfaces and the work area, removing processing residues, checking the fume extraction system, and verifying that cooling is working properly. These checks allow any anomalies to be identified early, reducing the risk of more complex interventions.

Extraordinary maintenance and technical assistance

Extraordinary maintenance, on the other hand, involves less frequent but more complex interventions, such as replacing worn components, recalibrating the optical system, or resolving specific faults.

In these cases, it is essential to be able to count on a qualified technical assistance service, capable of intervening quickly and effectively. A structured support allows to significantly reduce machine downtime and restore ideal operating conditions without significant impacts on production.

How long can a CO₂ laser machine last

If properly maintained, an industrial CO₂ laser system can deliver high performance for many years. Duration should not be understood only in terms of working hours, but as the machine’s ability to maintain precision, reliability and constant quality over time.

Well-structured preventive maintenance allows you to optimize the total cost of owning the laser system, valuing the initial investment throughout the machine’s life cycle.

What to consider before purchasing a laser system

Before purchasing a CO₂ laser system, it is important to evaluate not only the technical performance, but also aspects related to management and maintenance over time, such as:

- simplicity of routine maintenance operations

- quality and reliability of the laser source

- accessibility of main components

- availability of specialized technical assistance

- ongoing after-sales support

These factors have a significant impact on production efficiency and overall system life, resulting in an impact on operating and/or repair costs.

OT-LAS’s approach to machinery maintenance and life

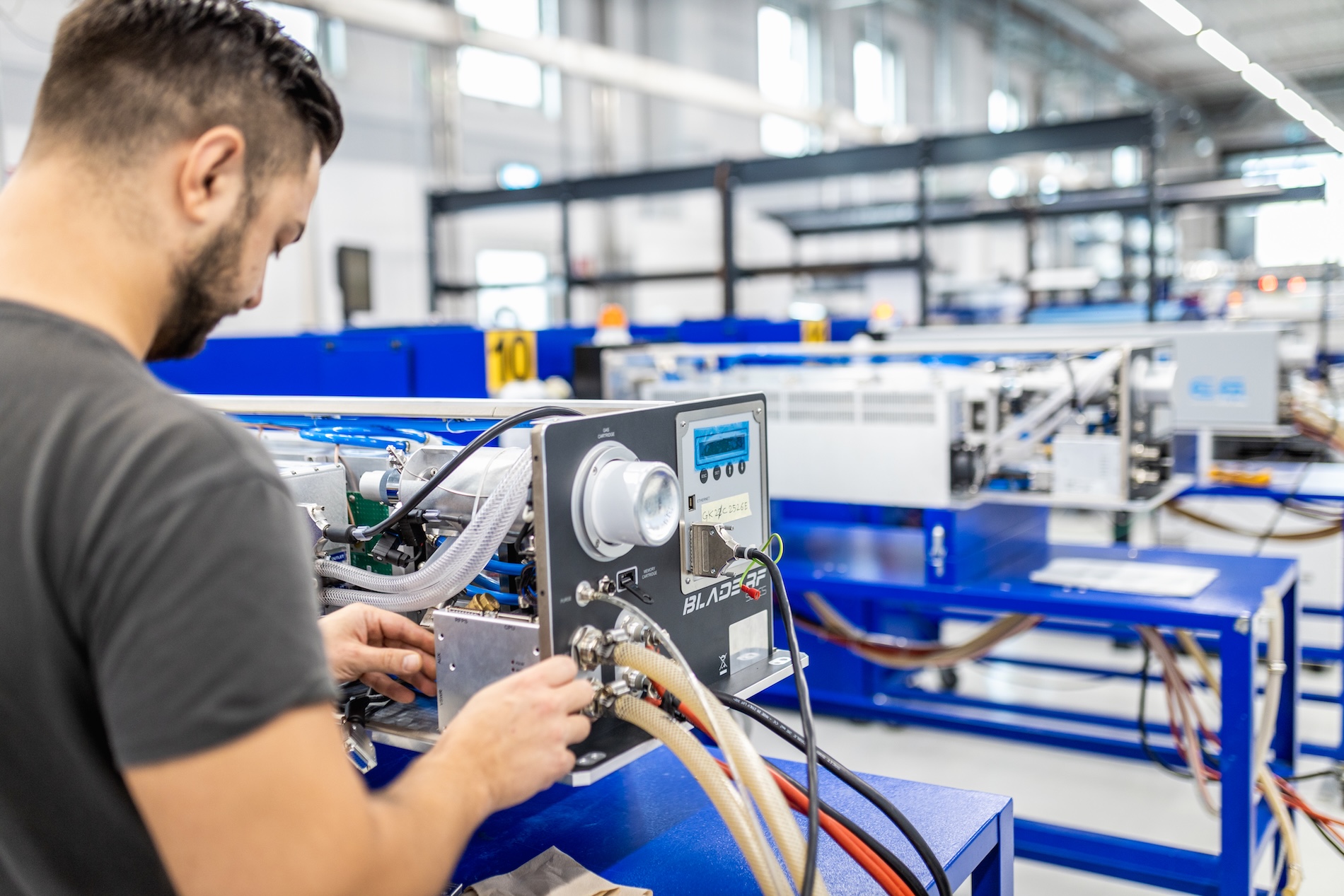

OT-LAS laser machines are designed and manufactured in Italy with the aim of ensuring reliability, precision and long life. The quality of the materials, the attention to design and a structured service of assistance allow to maintain high performance over time, in the face of proper maintenance.

OT-LAS supports customers not only in choosing the most suitable system, but also in operational management and maintenance. Technical support and proprietary technology ensure the peace of mind of competent and dedicated assistance to preserve the value of the investment.

Remote support: concrete support for production continuity

OT-LAS machines allow their technicians to operate even with remote assistance. This type of intervention allows for the analysis of anomalies, operating parameters, and reports directly remotely, reducing intervention times and operating costs.

Remote assistance is particularly useful for a quick analysis of the root cause of a malfunction, providing guidance to operators, or checking whether field intervention is necessary. In many cases, it allows the problem to be solved without interrupting production for a long time, contributing in a concrete way to the continuity of the process.

Contact us to receive information on the maintenance of our laser machines or to evaluate the solution best suited to your production needs.