The OT-LAS laser machines are directly developed in-house to guarantee the maximum accuracy and flexibility in processing. Furthermore, they offer the best power and speed performance even in case of large surfaces and complex materials such as marble. As a consequence, they are the ideal solution for the creation of wall coating and other interior design components.

Due to the very high quality of laser cutting and engraving, the OT-LAS laser systems can perform unique decorations of furniture and furnishing complements. Specialized expertise in this sector along with in-house development of the machines allow us to support you even with bespoke configurations.

Here are some OT-LAS advantages for you:

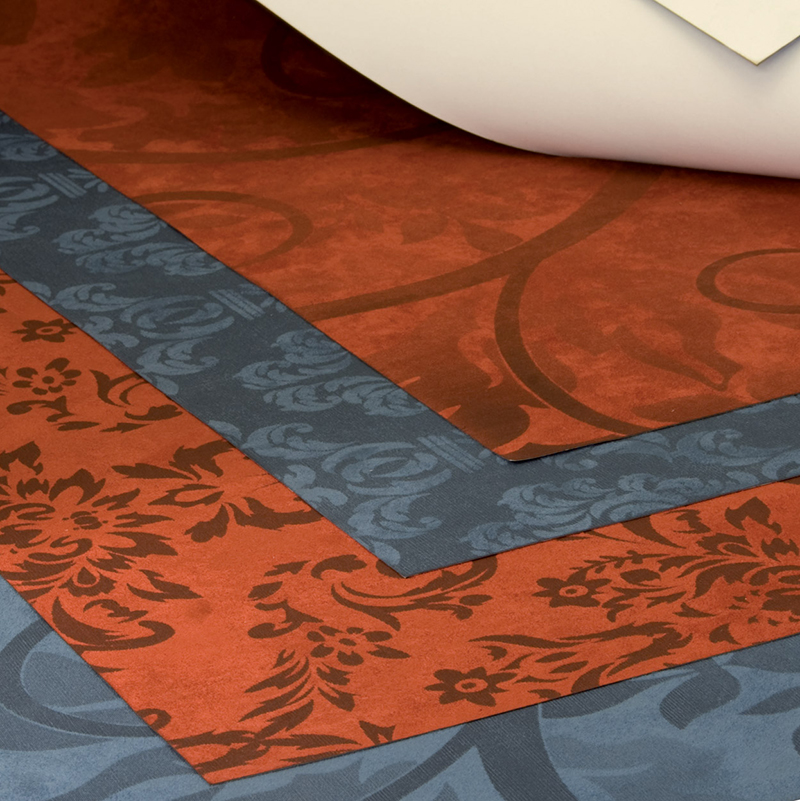

Due to the laser machines’ accuracy and versatility, cutting and decorating wallpaper is much more simple and effective. The possibility to realize really very complex patterns and drawings, with fine details and 3D effects, considerably widens the interior design horizons. Even engraving of furnishings and furniture in wood, glass, stone and plastics at very high levels of accuracy and speed represents an undeniable advantage. Any possible pattern, logo or decoration can come true in a very short time with flawless and permanent results over time. In addition, we have now been succeeding in processing large-sized marble surfaces in unimaginable time so far.

The laser machines can carry out customizations on all materials using a minimum quantity of power to start operations. That is why laser machines are an environment-friendly and cost-effective solution for your organization.

Here are some laser advantages for wall covering and interior design:

Call us to speak with one of our experts who will show you the solution that best meets your needs.

Service

Ph: (+39) 055 7760184

Email: service@otlas.it

Office

Ph: (+39) 055 7760183

Email: info@otlas.it

monday – friday

from 09.00 a.m. to 18.30 p.m.

Legal office

Via Baldanzese 17, 50041

Calenzano (FI)

Head office

Via Pantano 16/G, 50013

Campi Bisenzio (FI)

Offices

Via Cherzani 16/5, 50041

Calenzano (FI)

Company info

Laser solutions

©2025 Ot-las s.r.l. – Cod. Fisc e Reg Imp FI n. 04418930485 – P.Iva 04418930485 – REA FI: 448229 – Cap. Soc. € 154.621,14 i.v.s.