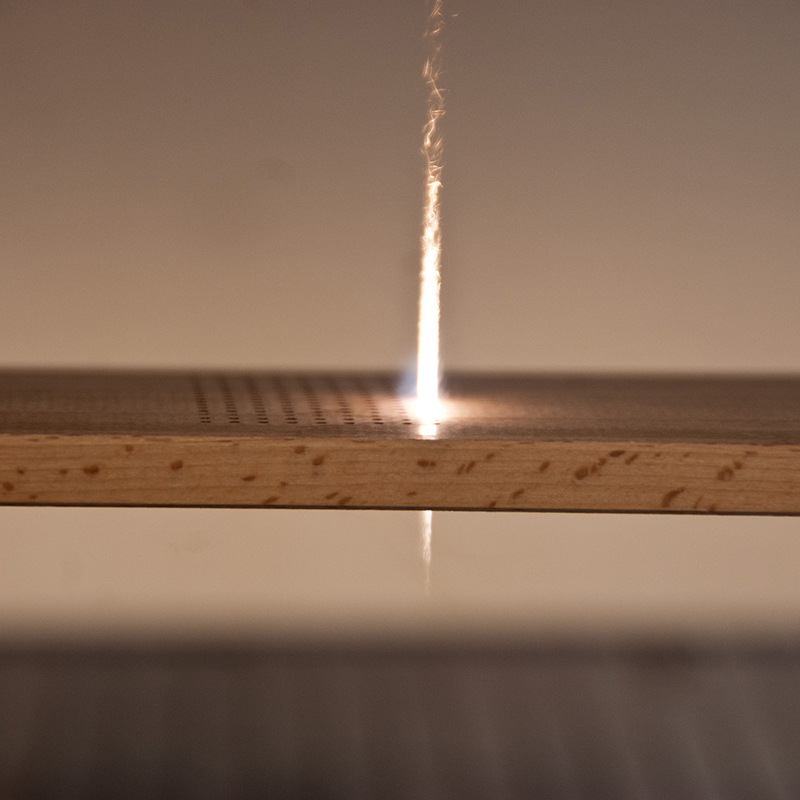

The use of laser machines finds application also in the acoustic sector thanks to the extreme precision and processing speed. The laser microperforation of materials such as wood, veneered wood and plastics allows obtaining sound-absorbing panels with perfect results. The laser processing stands out for its extreme neatness of edges and for its flexibility.

These are ideal advantages to obtain thousands of holes that are almost imperceptible to the eye but functional to noise absorption. Furthermore, OT-LAS laser machines require a minimum amount of energy for processing, thus allowing a significant saving of costs and resources. For this reason, they also stand out under an environmentally-friendly point of view with a low impact on the environment.

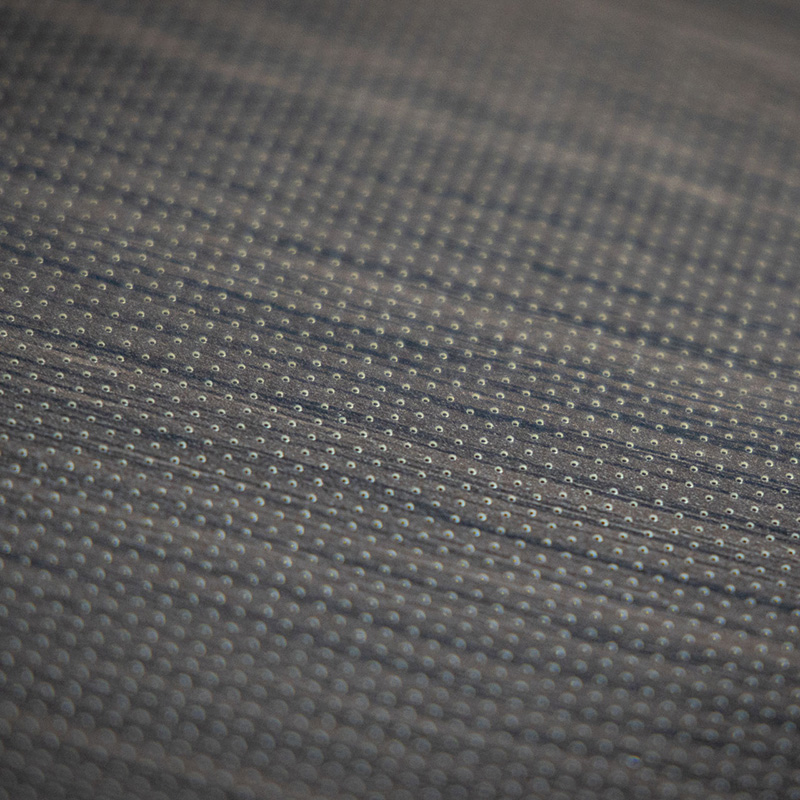

Unlike other microperforation systems, such as punching machines, the laser beam allows obtaining almost invisible microholes, with perfectly smooth and neat edges. This way, microperforation can also be performed on furniture surfaces, to the benefit of functionality without compromising the look and feel.

The flawless result and quality of processing make laser microperforation also ideal for the most elegant and stylish interior design. A unique advantage to customize high-quality coatings, furnishings, and panels with respect for materials and the final result.

Call us to speak with one of our experts who will show you the solution that best meets your needs.