Maximum Power

850 W

Maximum Area

1400×3500 mm

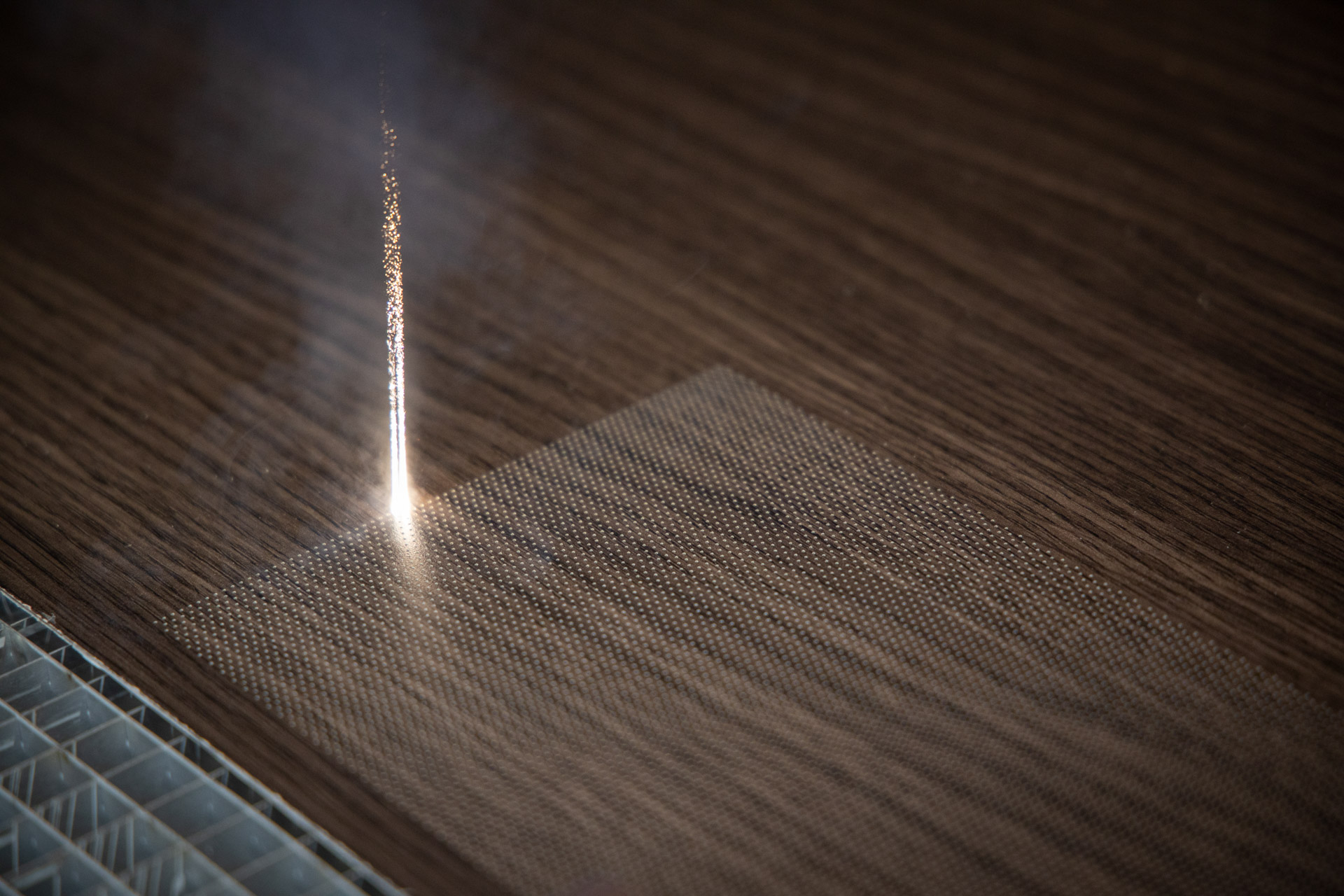

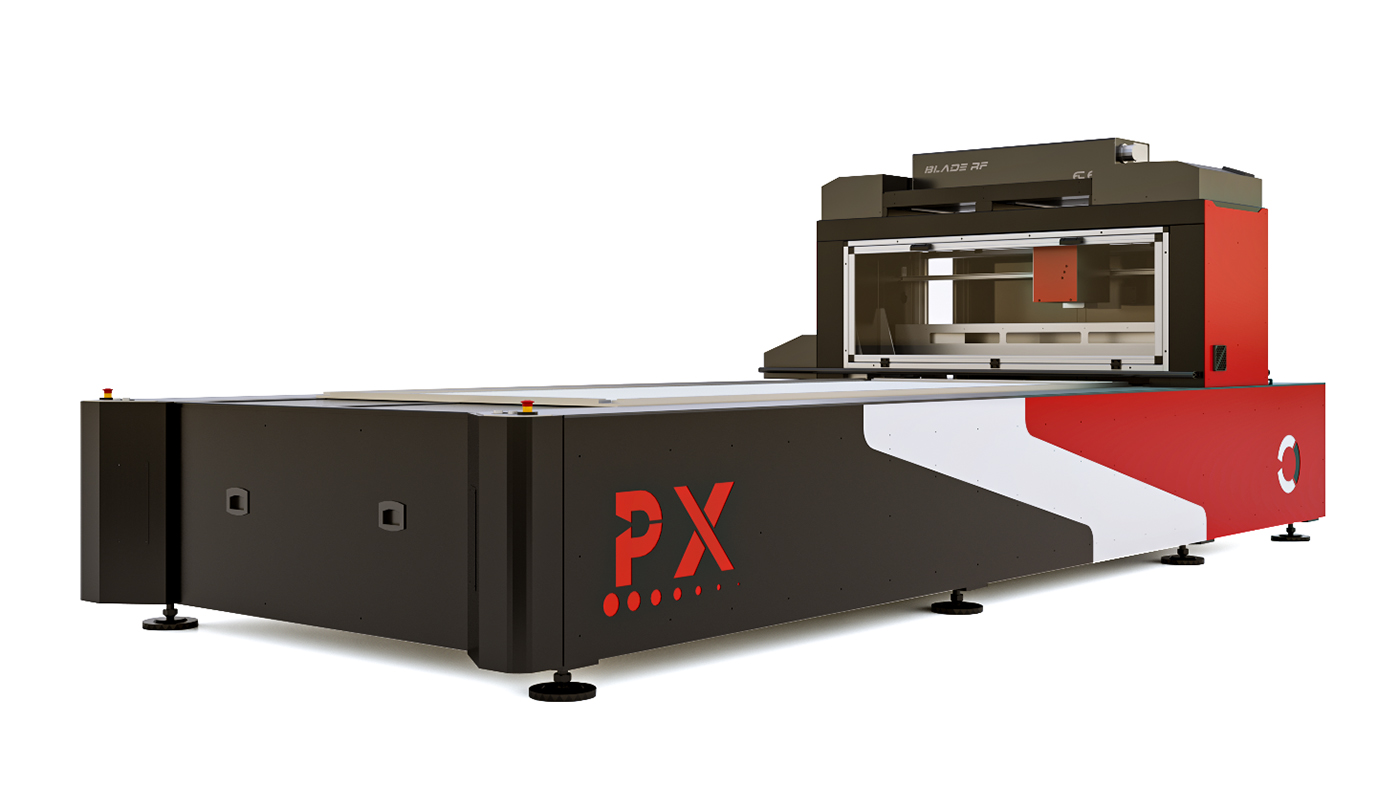

PX, the laser solution for acoustic and design panels

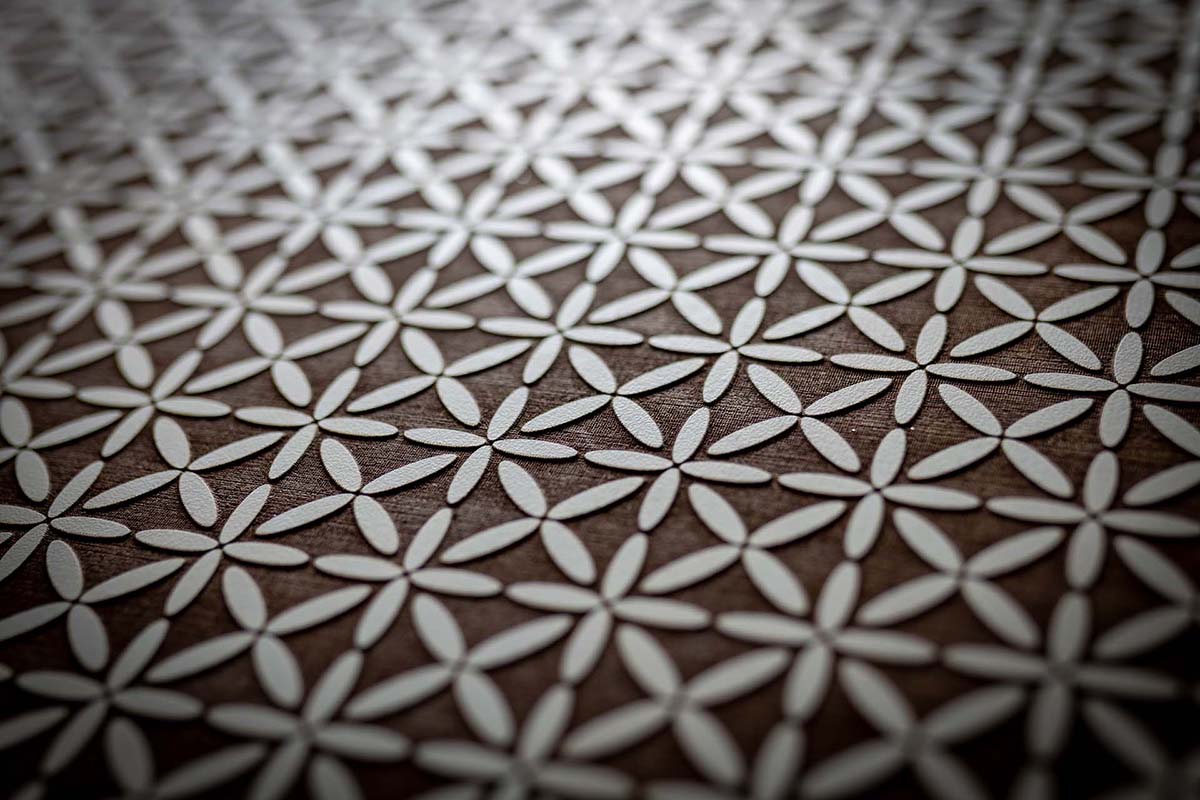

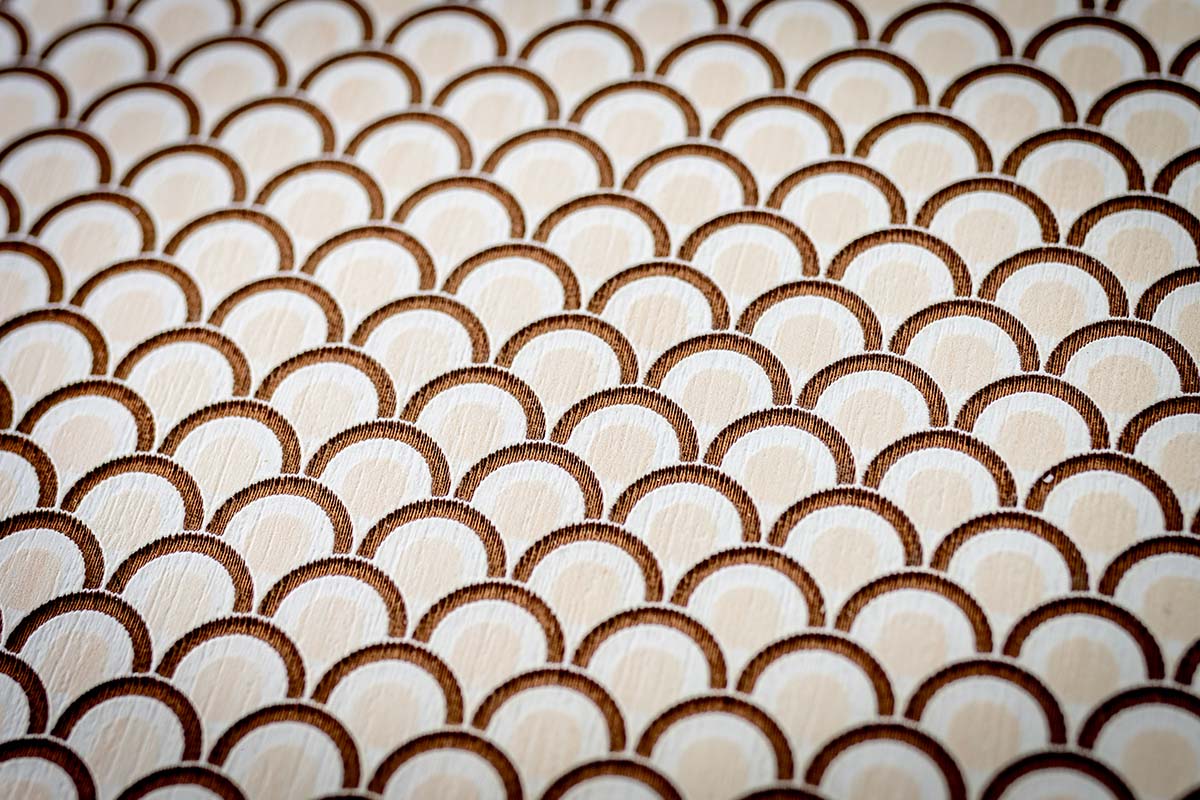

PX is the latest generation laser machine specially designed for microperforation of sound-absorbing panels with excellent results in terms of performance and speed. The versatility of the laser system and the impeccable quality of the workmanship meet the requirements of acoustics and interior design for all environments where it is necessary to reduce noise: from theatres to shopping malls, from airports to private areas.

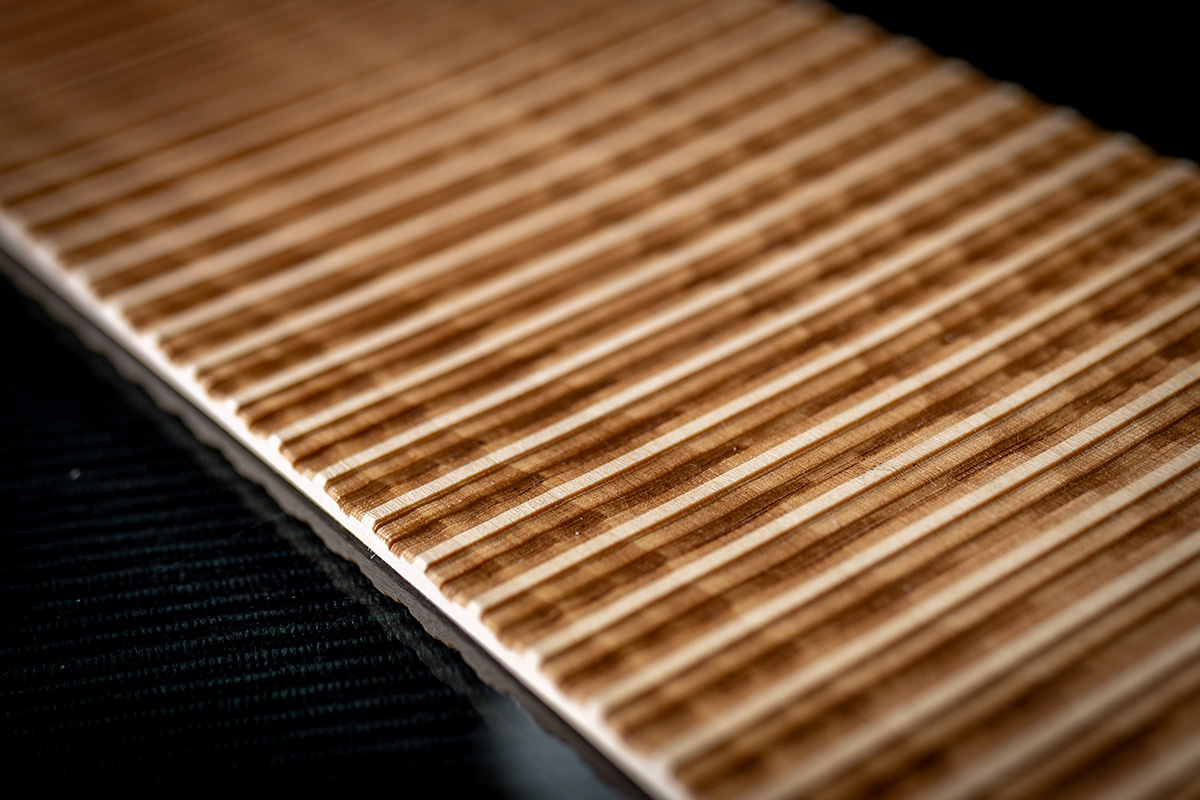

The extreme precision of the micro-holes, which do not require finishing, and the homogeneous distribution, even with complex patterns, offer a perfect combination of aesthetics, flexibility and functionality.

The materials that PX can work with:

- Wood

- MDF

- Rolled

- HPL

- Composites

All the advantages of PX for microperforation

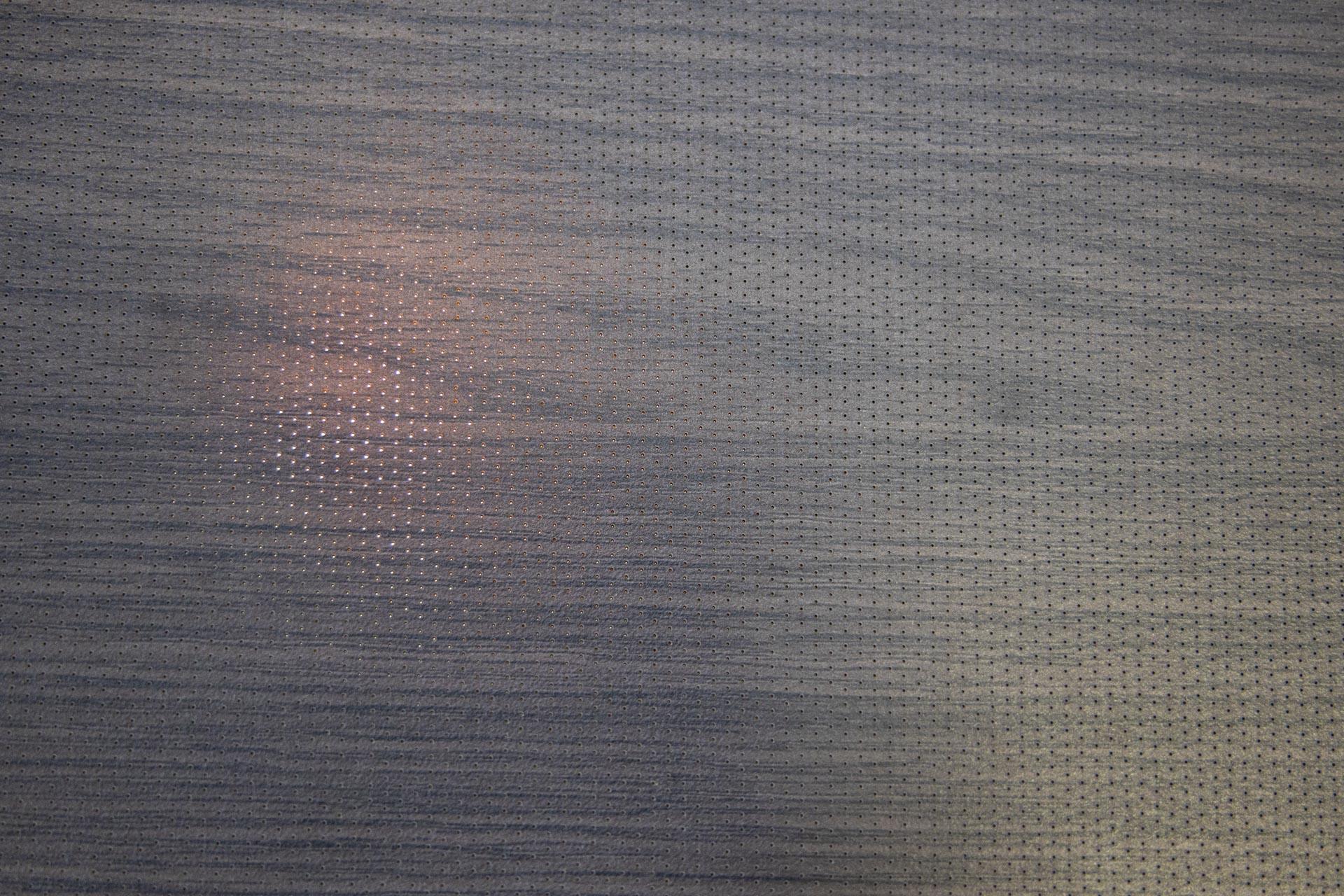

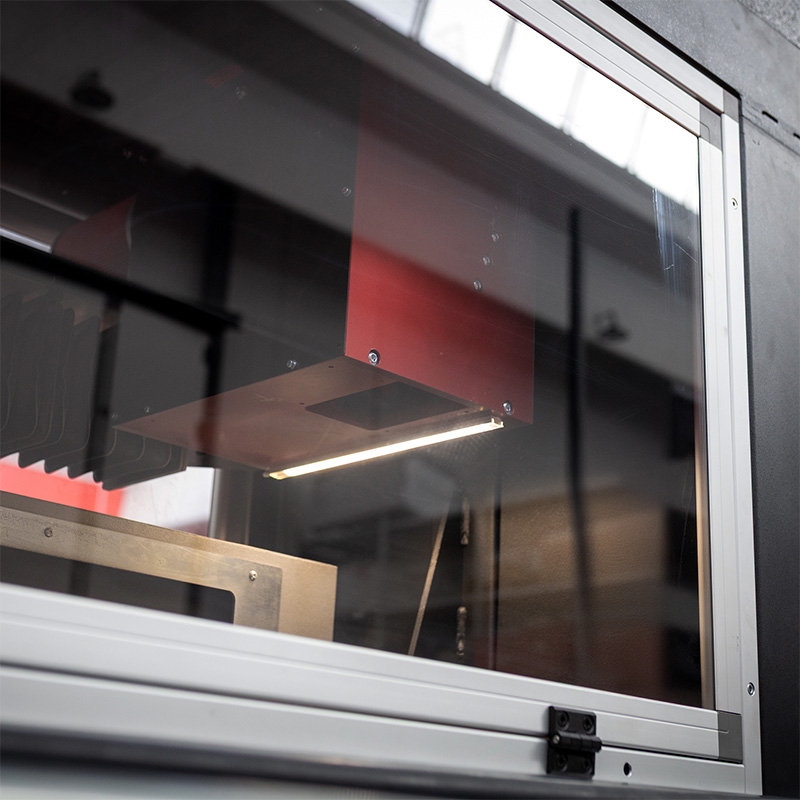

PX is the laser system designed and built entirely to revolutionize the field of noise absorption. Thanks to the unique 35 mm scanning head that moves along the working area, PX is the fastest solution for micro-perforation. The speed of execution and the creation of perfect holes, with imperceptible textures, make PX the most advanced solution among micro-drilling systems.

The PX highlights:

- Machine with fixed area 350x350mm for rapid microperforation.

- Faster microperforation process, thanks to the scanning head with optical aperture of 35mm.

- High precision laser spot, with a minimum diameter of 0.3mm which can be modulated to obtain micro-holes up to 1mm in diameter.

- Equipped with operating software for microperforation and graphic software for the realization of complex patterns and graphics.

- For each work it is possible to assign geometric and processing parameters and set any repetitions or compositions of drawings.

- Maximum flexibility even with complex patterns, with user friendly interface to set the distance between points on a same line, the distance between lines and shift between lines.

- Possibility to make drawings, even of size greater than 350x350 mm, using the matching between the areas and the movement of the scanning head along the X and Y axes.

- Green processing that reduces material waste and does not require pollutants.

Technical characteristics

Designed for unique performance in terms of speed, versatility and micro-perforation quality, PX allows you to create high-profile sound-absorbing panels for acoustics and interior design.

| Blade RF | 555 | 777 | 888 |

| Rated power (W) | 550 | 750 | 850 |

| Machine power (kW) | 10 | 12 | 13/13 |

| Fixed working area (mm) | 350×350 mm – nominal spot da 0.3 mm | ||

| Galvanometric scanning head | Optical aperture 35mm | ||

| Total useful area (mm) | 1400×3500 with single area 350×350 | ||

| Electric Power Supply (VAC) | machine: 400 3F+T ±10% – 50 Hz chiller: 400 3F+T ±10% – 50 Hz | ||

Software for PX

A graphic and operating software with specific Corel Draw graphic engine for the realization of files and for the entire system functioning. For each work, it is possible to assign geometric parameters, processing parameters and set any drawing repetitions or compositions, in case the system is equipped with automatic table.

A machine management software that can open various formats such as PLT, BMP, etc. Moreover, Engraving allows setting the arrangement and frequency of the points on panels as well as speed and power parameters, and creating processing lists.

Some processing made with PX