Leather laser treatment is an increasingly used technique in the creation of products for the fashion, automotive and interior design sectors. Laser cutting and engraving of leather, whether real or synthetic, can really offer unparalleled advantages, for both businesses and the environment. The laser allows considerably reducing material waste while streamlining production times and costs. These definitely are two significant added values for future customisation and the planet protection.

What are the laser advantages in terms of leather treatment that is unique and exclusive?

Though leather boasts never-ending appeal, it is such a delicate material. The leather cutting and engraving mechanical systems involve long processing times and high risk of damage. Due to the CO2 laser systems, flawless finishing can be easily and rapidly performed, streamlining production and encouraging versatility in processing. Furthermore, the leather laser cutting and engraving entail less waste compared to traditional methods and require fewer power resources. As a result, the use of laser systems in the leather industry has allowed considerably reducing the environmental impact.

The advantages of laser cutting and engraving:

- The utmost accuracy

- Rapid processing

- Countless possible effects

- Performance of complex patterns

- No tool change or wear

- Less processing waste

- Less use of power resources

- No material deformation

- Traceable processing

What leather products can be laser engraved?

Initially, the leather laser treatment aimed at the fashion market, with laser cutting and engraving for leather accessories, footwear and clothing. Over the last years, the increasingly sought-after customisation and refined treatments in other sectors too have made the laser technology more and more valued. Nowadays, the CO2 laser is the undisputed protagonist of the leading fashion businesses as well as of the automotive and interior design manufacturing sectors. In addition to shoes, bags, wallets, purses, accessories, insoles and uppers, the laser systems can also process the leather car interiors and exclusive interior design elements.

What treatments can we perform by laser?

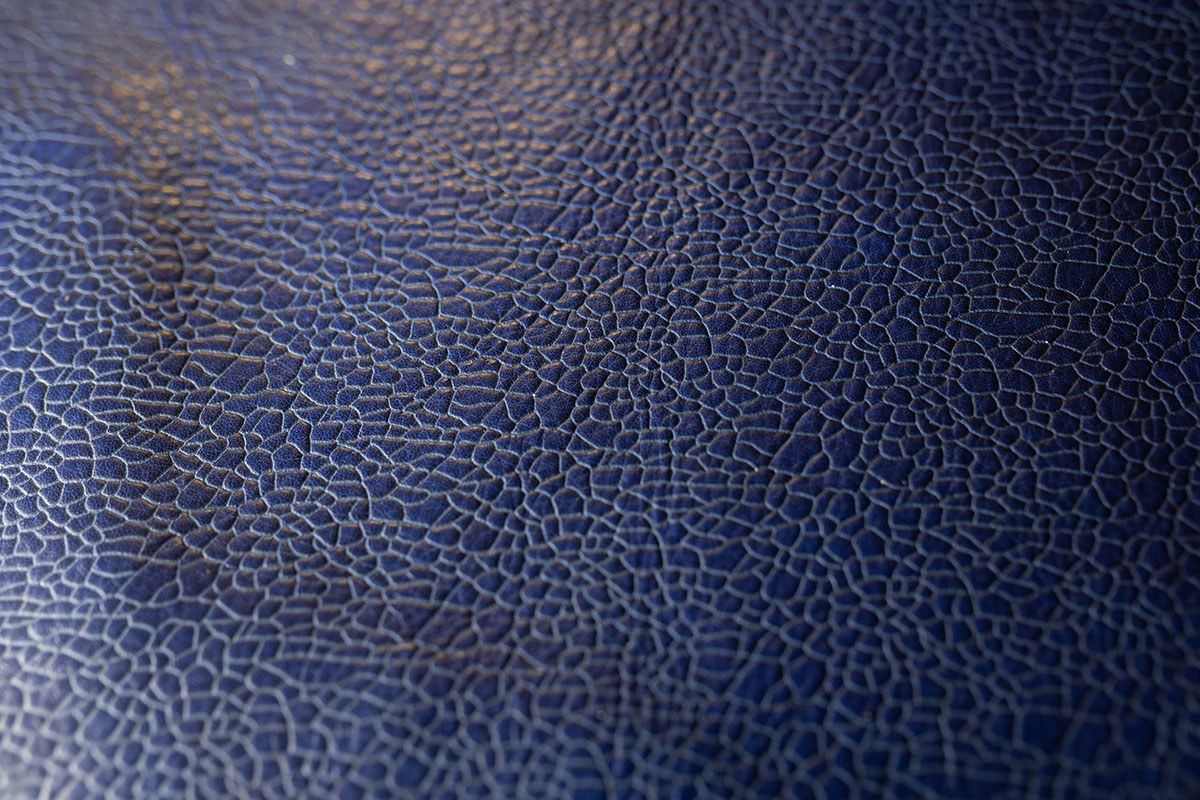

The leather laser cutting and engraving now allow getting extraordinary accuracy, with neat and perfectly defined edges. The leather laser engraving brings about a sort of embossed effect that depends on the type and colour of the leather being treated. For instance, the colour contrast stands out more in light than in dark leather. Moreover, the laser versatility allows marking complex graphic design and patterns in a very short time. Any leather laser treatment can be rapidly performed due to breakthrough software and technology and generates lasting effects over time.

What kinds of leather can be laser engraved?

The laser systems for the leather treatment are suitable to both the real and synthetic leather. The most used materials are:

- Natural leather

- Suede

- Chamois leather

- Nubuck

- Alcantara

- Faux leather

Careful consideration of the kind of material to be cut or engraved is necessary so as to set up the right speed and power parameters according to the kind of leather. Furthermore, the laser allows using solutions that can enhance the final result, in terms of style effects and manufacturing aspects.

Can the laser engraving smell be eliminated?

For sure, in a number of ways. The laser cuts or marks leather by means of a infrared light source that results in the typical ‘burnt’ leather smell. There are now a number of solutions to eliminate such unpleasant residue. From the application of surface sticky films or the use of products to be applied before or after laser treatment to industrial washing, each company chooses a solution considered to be the best to remove the treatment smell.

What are the Ot-Las machines’ advantages for leather treatment?

The Ot-Las systems for the laser cutting and marking of leather are specifically designed and in-house manufactured so as to offer the utmost performance, in terms of power and speed and more. The first asset definitely is the high quality of the final result, that is the combination of a number of aspects carefully dealt with:

- high power means rapidly treating leather, thus eliminating any risk of burning the material

- high resolution guarantees unique accuracy and top-class finishing

- a wide array of software solutions can ensure all necessary tools to carry out processes

- expertise in materials allows choosing the most suitable configuration

Furthermore, the Ot-Las CO2 laser systems perfectly suit to numberless customisation solutions making way for the creativity that really makes a product one-of-a-kind and exclusive.

Find out all detailed information about our machines for the leather laser treatment or contact us for more info.