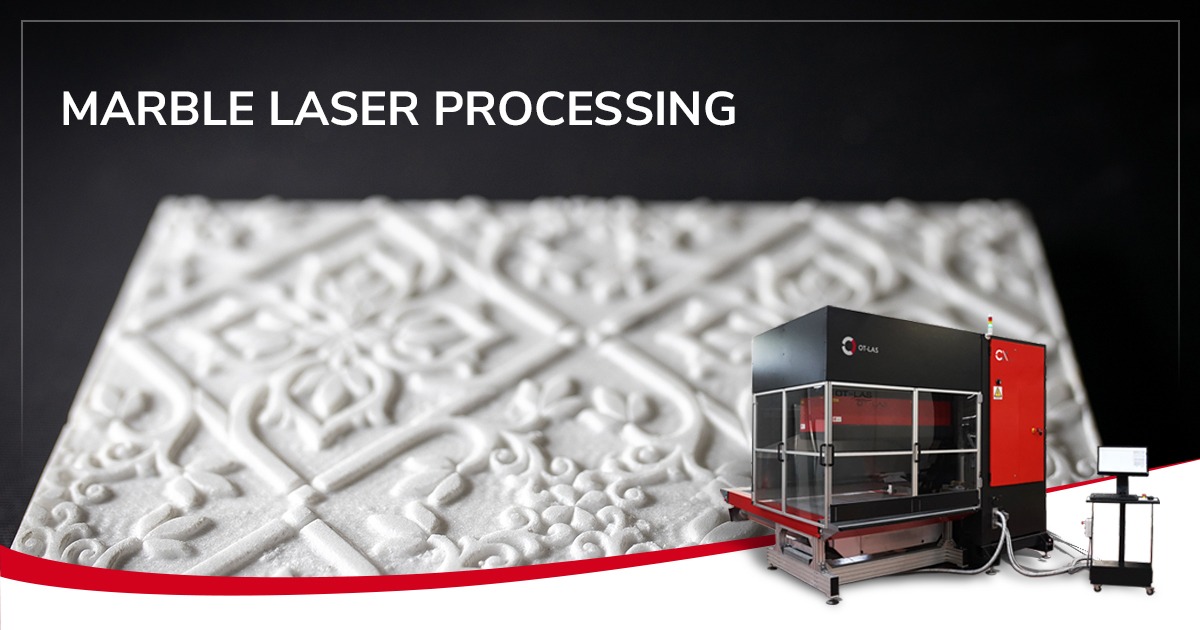

Marble is one of the materials that are more suitable to laser processing. Laser processing marble allows creating unexpected effects, with the finest decorations and bas-reliefs.

Ot-Las has specifically designed the new CX XL machine with 1200 watt laser power for this sector, the ideal solution to process large-sized surfaces as well as little tiles. With its area ranging from 700×700 up to maximum 1,600×1,600 mm, the CX XL machine can meet all operating needs. The 1200 watt power is necessary not to lose productivity since due to the higher power we can guarantee reduced processing time and deeper excavation.

Successful features of laser technology:

- Complex and unique drawings easy to realize

- Low power consumption

- Reduced environmental impact (there are not any residues from processing to be disposed of, as for instance in waterjet processing)

- User-friendliness

- Little maintenance

How the system operates

The Ot-Las laser machines are called galvanometer: that means the laser beam ‘deviation’ occurs through two mirrors moving at a very high speed. Therefore, moving motors or mechanical parts are totally absent. The mirrors’ motion is controlled by the CN (numeric control) of the machine, that turns information (drawings) processed by Corel Draw (one of the most popular graphics programs worldwide) into x-y-z coordinates to be transferred to 3 electric motors, that are called galvanometer.

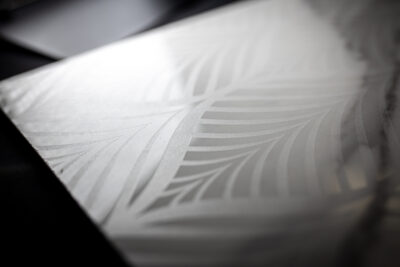

Marble excavation (engraving) can only be superficial or, decreasing speed or carrying out more passages over the same point, levels of higher depth can be obtained. This type of processing can also apply to other materials suitable for excavation, such as wood for instance. On the other hand, glass and ceramics cannot be excavated.

Some marble processing

Considerations on the machine

Our CX XL laser machine with 1200 watt power is suitable for marble, ceramics and wood (such as MDF and plywood), glass and stone processing.

The 1200 watt laser is less recommended for processing requiring less power (too unnecessary power could damage the material), so if we wanted to treat leather and textiles with great results we could choose the RF888 (850 watt) laser, that is a special version for textiles. Of course, the laser machines with lower power can also treat all other materials such as glass, marble, wood and so on but they require more processing time.

The CX XL configurations are two:

- With moving table, to handle working areas up to 1,600×3,600mm, where large sheets or medium-sized objects can be placed and the axes motion can be used to cover all the working table.

- With Conveyor system, due to which even much larger pieces can be treated (1,600mm x any length) exploiting the metal conveyor motion. By this system, even smaller objects can be treated, but their positioning is certainly slower than through the moving table option.

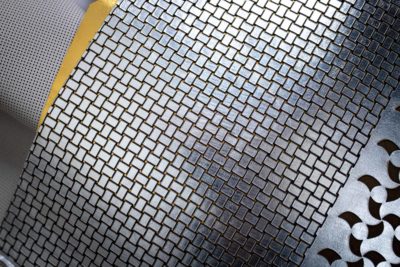

Other processing:

With a view to making treatments even more precious, OT-LAS has established co-operations with centers for the processing and development of new solutions for a long time now.

For this reason, the most popular treatments with the customers of our customers are those in which material processing techniques combine with laser technology, thus making the final result unrecognizable and therefore not easily reproducible.