CO2 laser machines are now indispensable in many sectors of the industry for very high precision machining, such as engraving, marking and laser microperforation. To ensure optimum performance, it is essential that machines are properly maintained on a regular basis. Laser system maintenance not only reduces downtime by avoiding malfunctions, but also preserves functionality in the long term, prolonging the effective life of systems and optimizing the initial investment. Let’s see what the main advantages of maintenance are, according to regulations and best practices for the care of CO2 laser machines.

What is industrial maintenance?

Industrial maintenance includes all operations necessary to keep a machine efficient, reduce the risk of failure and extend its operating life. According to frequency and mode, the maintenance of industrial machines is divided into different types, including ordinary maintenance and extraordinary maintenance. In the case of laser machines, proper maintenance management ensures that the best conditions are maintained to ensure precise machining, lower energy consumption and safety for operators. Without regular checks, industrial machines can suffer from malfunctions and damage due to wear or improper use.

The benefits of proper maintenance

It is normal that the maintenance of laser machines takes up part of the company’s time and resources. But when the planned maintenance work is not carried out it is easy to run into production blocks, with considerable economic and operational damage. The result is that, in order to save the time and cost of maintenance interventions, you end up with much higher costs. In addition, failure to check the functionality of machinery can lead to even more serious consequences on the regular performance of work activities.

On the contrary, regular maintenance offers many advantages, for example:

- Increased machine life → due to regular cleaning and checking of components, the wear of the laser system is slowed down.

- Best cutting and engraving quality → an efficient laser machine in optimal conditions performs more precise machining, without the risk of imperfections.

- Lower repair costs and downtime risk → Preventive interventions reduce the need for costly replacements and the risk of operational outages. The machine shutdown necessary for maintenance is programmed at the most appropriate time, while a sudden interruption can occur in the middle of a production emergency.

What types of maintenance are there for laser machines?

What is meant by maintenance? The maintenance of industrial machines can be divided into:

- Routine maintenance, that is the actions and routine checks carried out regularly by operators, such as general cleaning of the machine and checking of components.

- Extraordinary maintenance, which involves more complex interventions carried out by specialised technicians to repair faults or replace worn-out components.

Routine maintenance of laser machines

In the routine maintenance of laser systems, regular cleaning and periodic machine cleaning are essential. Daily cleaning operations include:

- Removal of dust and processing residues from machine surfaces.

- Control of cooling system and coolant levels.

- Check the correct functioning of the accessories for the operation of the machine such as compressor or fume extraction system.

Extraordinary laser machine maintenance

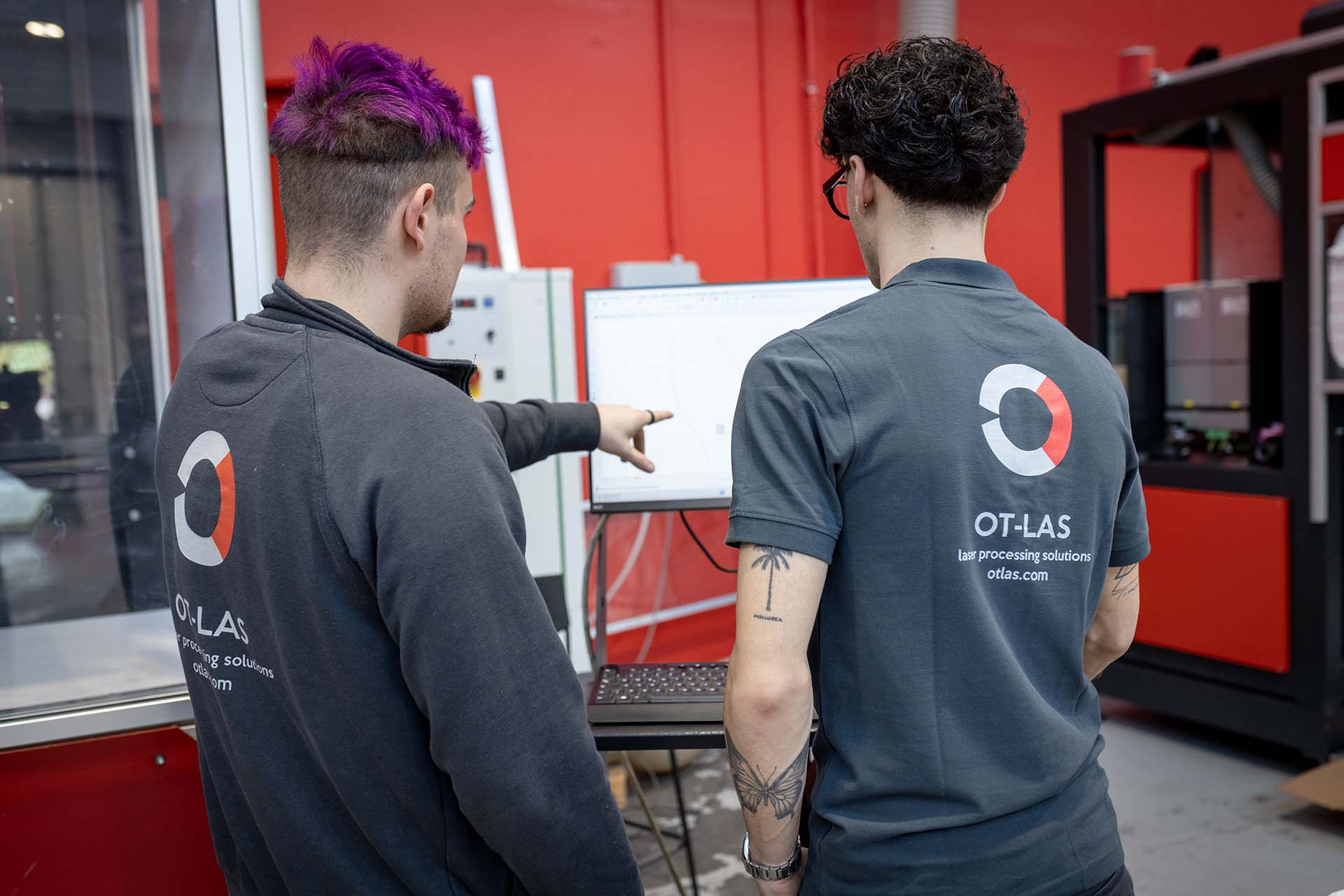

The extraordinary maintenance of the CO2 laser machine is not frequent. If the customer reports faults or malfunctions, OT-LAS technicians can intervene remotely to identify the cause and implement the necessary solution. In case of more complex interventions to be done on the field and not resolvable remotely, OT-LAS technicians are prepared to intervene with timeliness and efficiency.

OT-LAS maintenance support

The OT-LAS laser machines are designed and manufactured in-house to guarantee robustness, precision and reliability even in the long term. The high quality of laser systems and each component and material used ensure high-profile performance and the advantage of a long service life, always with proper maintenance. OT-LAS technicians are always available to advise customers on the correct maintenance of laser systems and intervene if necessary.

Discover the OT-LAS laser system tailored for your company or contact us to receive information on the maintenance of your laser machine.