In the automotive sector, the transition towards sustainable production is now an indispensable priority. Car manufacturers are looking for solutions that reduce energy consumption, reducing waste and reducing environmental impact. CO₂ laser technology responds to this need as one of the most efficient, flexible and green solutions for the automotive industry. Thanks to innovative systems such as the RX OT-LAS kit for 3D laser cutting it is possible to improve production quality and reduce waste and energy costs.

Energy efficiency and sustainability in automotive production

Automotive is among the most energy-intensive industrial sectors: painting, cutting, marking and decoration require intensive processes, which are often difficult to optimize. Regulatory pressure and growing sensitivity towards sustainability push manufacturers to look for cleaner and more performing processing solutions. CO₂ laser systems meet this need by:

- Lower energy consumption than many traditional engraving and marking technologies;

- A process without contact with mechanical tools, therefore with less risk of damage to materials;

- Greater precision that eliminates rework and reduces waste, allowing greater optimization in the supply of materials.

- The absence of inks and chemicals needed with other technologies to achieve particular effects.

In other words, the CO₂ laser transforms production from a high environmental impact process to an efficient and sustainable flow.

The role of the CO₂ laser in automotive production

The CO₂ laser is now used in numerous phases of the automotive supply chain thanks to its infinite customization possibilities. From the marking of plastic components to the decoration of internal coverings, up to the micro-perforation of materials for ventilated seats. Each application contributes to improving the overall environmental balance of the process and guarantees accuracy and production versatility. Laser processing involves less dispersion, lower consumption and high repeatability of the result, ideal even for large productions. Furthermore, the absence of mechanical tools reduces maintenance and wear, with an additional environmental and economic advantage.

RX kit for robots: efficiency and flexibility in a single system

The OT-LAS 3D laser cutting RX kit represents one of the most advanced solutions for those who want to integrate CO₂ laser into their production processes. Designed for maximum efficiency, the kit allows for high-quality machining, high execution speed and low operating costs.

Among the main advantages:

- Energy optimization: the robot is coupled with the CO2 laser source via a system of mirrors that make up the optical path and guarantee the perfect transfer of laser power to the cutting head.

- High productivity: the processing speed thanks to the integration of the scanning head improves cycle times and allows rapid and high quality production, with 3D processing free of burrs and traces of carbonization.

- Minimum maintenance: the solid structure and high reliability of the source allow maintenance to be reduced to just one annual technical intervention.

The RX kit adapts perfectly to automated lines for micro-perforation, engraving and laser cutting, bringing sustainability and innovation to companies.

Laser microperforation: comfort and sustainability

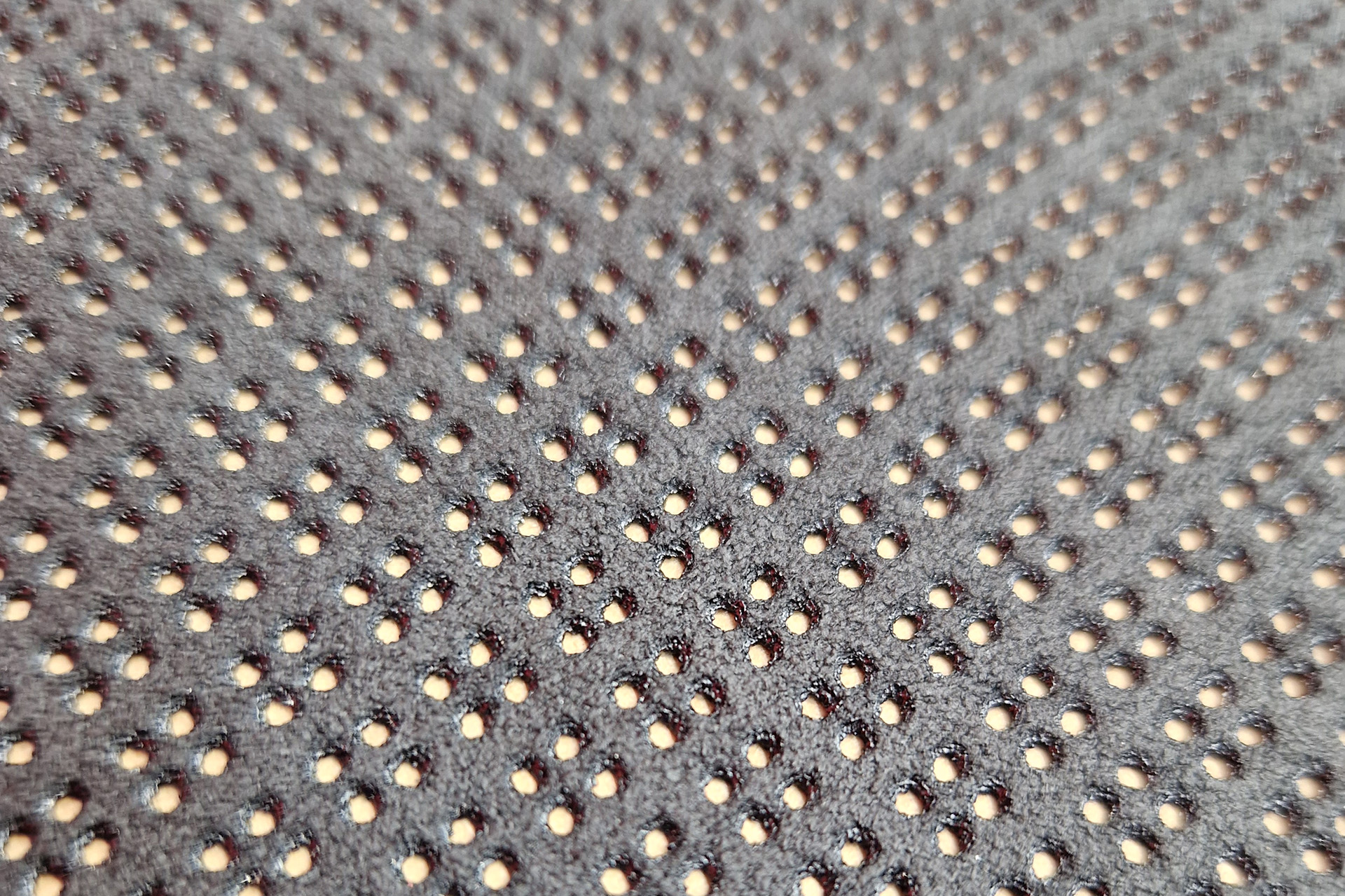

One of the most requested applications in the automotive sector is the microperforation of materials for seats, panels and internal coverings. The CO₂ laser allows you to obtain micrometric precision holes, improving breathability without compromising the resistance of the material.

Unlike mechanical techniques, laser microperforation:

- It does not generate processing waste, reducing waste;

- It does not require mechanical tools to be replaced during processing, avoiding machine downtime;

- Consumes less overall energy per production cycle, to the benefit of environmental resources and savings for the company.

The result is a clean, rapid and sustainable process, which can also be perfectly integrated into roll-to-roll lines.

CO₂ laser cutting: waste-free precision

In automotive components, 3D laser technology allows you to cut technical fabrics, plastics and films with extreme accuracy, without distortions. The quality of the edge obtained with the laser avoids having to intervene later in the finishing and the absence of waste means less waste production. Furthermore, the ability to program optimized routes via CAD software reduces processing times. What results is a more linear and efficient production flow.

Laser decoration: green aesthetics and customization

CO₂ laser decoration offers endless creative possibilities, with minimal environmental impact. The laser allows you to mark and engrave logos, textures and aesthetic motifs on plastic, painted or laminated surfaces, replacing polluting processes such as screen printing or pad printing. Furthermore, the laser decoration is completely digital: just update the graphic file to change the design and pattern, without having to resort to new systems or consumables. This is why OT-LAS laser machines ensure a competitive advantage for all companies seeking customization and sustainability.

Roll-to-roll production: continuity and energy saving

The integration of CO₂ laser technology into roll-to-roll systems allows you to work continuously on material coils, reducing downtime and starting consumption. This approach is also ideal for the automotive sector, where mass production must combine quality and cost reduction.

A concrete step towards sustainable production

OT-LAS CO₂ laser systems for automotive are designed and created for all production companies that want to adopt truly sustainable technology. Thanks to cleaner and more automated processes, the customization of components also becomes green, getting rid of toxic products and material waste. This is why cutting-edge solutions such as the RX kit for 3D laser cutting ensure low-impact and highly competitive automotive production. A conscious and advantageous choice in a market that increasingly looks at environmental responsibility.

Discover the RX kit for robots and other laser systems for automotive production.