The CO2 laser is one of the most widespread technologies for engraving natural materials, such as stone, wood and fabric, with results of remarkable elegance and functionality. The performance in terms of precision, customization and sustainability make CO2 laser systems indispensable for a wide range of applications. From interior design to fashion, from architecture to furniture, to name just a few, there are many sectors that have adopted this technology. Let’s find out how the CO2 laser works, which natural materials it can work with and what are the advantages over traditional methods.

What is the CO2 laser for engraving natural materials

The CO2 laser for engraving natural materials is an advanced technology that combines precision, speed and sustainability. Thanks to the power of the laser beam and the galvanometric scanning head for the movement and focusing of the beam, it is possible to obtain engravings on wood, fabrics and natural stones of the highest quality, also ideal for interior design and furniture. The laser’s efficiency and accuracy increase productivity, reducing operating costs and environmental impact while respecting the natural beauty of the material.

What is the difference between laser engraving and laser marking?

Although the two terms are often used as synonyms, engraving and laser marking indicate two distinct processes:

- CO2 laser engraving: removes the material from the surface, creating a visible and permanent groove. It is ideal for drawings, decorations, patterns and writings with three-dimensional effect.

- CO2 laser marking: changes the material only on the surface, often creating a color contrast (blackening or discoloration) due to the thermal effect. It is perfect for identification codes, serial numbers, logos or graphics that do not require a deeper engraving.

Both processes are contactless, that is without contact of a mechanical tool with the object. This feature significantly reduces the risk of deformation of natural materials and saves on system wear.

Which natural materials can be processed with the CO2 laser?

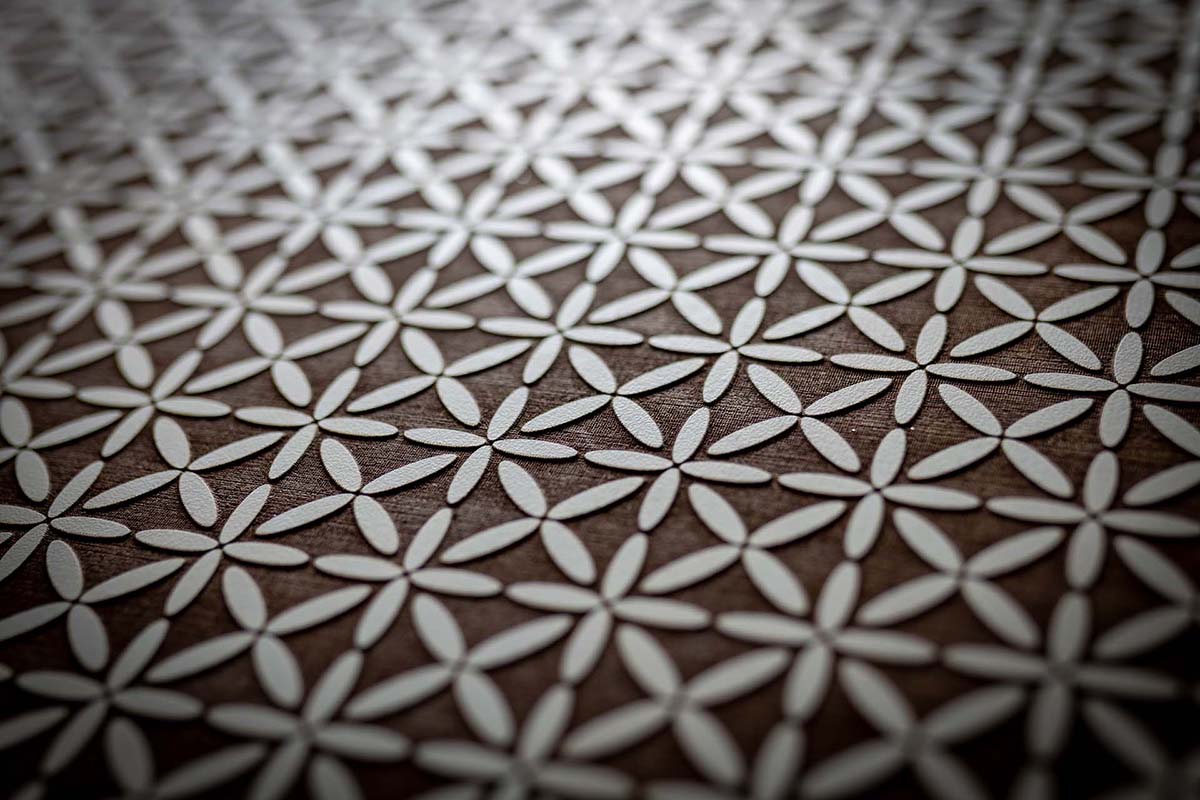

One of the strengths of the CO2 laser is its outstanding compatibility with a wide range of natural materials used that require particular care and accuracy. This advantage makes the laser a perfect technology for interior design companies. The main organic materials processed by laser include:

Micro-drilling and engraving of wood

Wood is a natural material that has always been appreciated in interior design for its versatility and performance. The range of textures, shades and veins, the warm and timeless aesthetic, the insulating properties, both thermal and acoustic, make it a valuable ally. For these reasons wood is widely used to make furniture, floors, vertical cladding and decorative elements.

In recent years, the choice to use laser for engraving wood has revolutionized the sector with a level of customization and functionality previously unattainable. The CO2 laser is suitable for engraving different types of wood, such as solid wood, plywood, chipboard, teak, cherry, maple, oak, bamboo, beech, cork, not to mention veneers and multilayer wood. In addition, the CO2 laser allows to obtain unique textures and engravings on wood refined and complex in full respect of the material.

In addition to the engraving, the micro-drilling of wood with special laser machines makes it possible to obtain sound-absorbing acoustic panels of exceptional efficiency. Systems such as CX Microperforation and PX allow to obtain also aesthetically valuable sound absorbing textures and patterns, thanks to the extraordinary precision of the microholes and their distribution, easily modifiable via software.

Laser for tissue processing

Natural fabrics have also rediscovered a leading role in interior design. Often produced with sustainable methods, fabrics such as cotton, linen and hemp bring freshness and harmony to the environment, improving the quality of the environment. In addition, the natural elegance of these materials makes it possible to make coatings, upholstery, curtains and pillows of particular beauty.

The use of laser for fabric processing has introduced a turning point in terms of productivity, sustainability and customization. The laser can process a wide range of natural fabrics such as silk, jute, cotton and linen, in addition to synthetic fabrics. The laser cutting systems for fabric allow to cut the material with extreme precision leaving the edges perfectly sealed.

Thanks to the CO2 laser you can achieve very special effects, such as graphics, discoloration, worn effect and unique patterns with extraordinary speed and, above all, without polluting. In fact, laser technology does not require the use of inks or sanding or polluting or toxic processes, protecting the environment and the health of operators. Advanced laser technology such as OT-LAS’s CX XL also offers additional advantages such as cutting and engraving directly from the roll and combining processing in a single operation.

Laser marking and engraving for leather and fabric

Among the fabrics of natural origin, leather has always been particularly successful in design upholstery. Precious and resistant, the leather gives a touch of exclusive class to both classic and modern environments, giving uniqueness and value to armchairs, sofas, beds and seats. Thanks to the laser it is possible to work different types of skin reducing the risk of damaging the material, although durable, must be treated gently. Natural leather, nubuck, suede can be worked with refinement and precision to create cozy and sophisticated furnishings and coverings.

Laser engraving for marble and stone

Marble and natural stone are materials capable of enhancing any environment with scenic effects and inimitable textures. The timeless class of marble, with its precious veins and the wide range of possible finishes find space in interior design in different forms and types of furniture and coating. At the same time, natural stone stands out for its durability and performance, with insulating properties and smooth or rough surfaces that create sophisticated play of light and shadow.

CO2 laser systems can cut marble and other natural stones, such as granite, onyx, quartz, pebbles, malachite, lapis lazuli, agate, slate and travertine, with surprising versatility. From the processing to obtain brushed surfaces, smoothed or flame effects or embossing to engravings of fine writing and decoration, the laser opens stylistic horizons of exceptional creativity. In addition, the precision of the laser beam and contactless processing allow to minimize material waste, also reducing the impact on the environment.

Some laser machines offer specific advantages for machining on certain materials, such as OT-LAS machines for machining on wood, fabric or marble.

Why is CO2 laser technology cheaper than traditional methods?

Unlike technologies such as punching, milling, printing or chemical engraving, the CO2 laser offers valuable advantages in the engraving of natural materials:

Absolute precision

Thanks to the high-definition optics, the laser allows you to create fine details on even complex surfaces with the highest quality.

Unrivalled flexibility

A single laser system can process dozens of different materials, with varying shapes and sizes, offering unprecedented production versatility.

Aesthetic customization

The CO2 laser can achieve elegant finishes, fine graphic effects, custom textures and artistic details with superior quality. Its performance allows infinite customization in response to market needs.

No tool contact or wear

The laser does not require any tools to process the natural material, so it avoids the risk of breakage, tool wear or unwanted residues.

Sustainability and low consumption

The CO2 laser is a green choice in line with the objectives of sustainable industry. It offers reduced consumption, reduces material waste and does not require inks or chemicals to achieve the desired effects.

Where is CO2 laser used? Industrial and creative applications

Thanks to its characteristics, the CO2 laser is used in many production contexts related to furniture and not only. The sectors that use it include, for example:

- Leather industry: for cuts and engravings on coatings, accessories, liners with elegant and refined results

- Interior design: for decorations and microperforations on wood, stone and fabric, marking and engraving of furniture and coatings in different materials with high-profile effects.

- Fashion and textiles: for the recycling of textile materials and for cutting and marking on fabrics also with machines for processing directly from rolls.

- Luxury packaging: for engravings on cardboard and leather for exclusive packaging

- Industrial traceability: for marking codes, dates, QRcode and logos on different materials.

- Automotive: for the realization of custom details and coatings also with special textures and processing

These are some of the industries that have adopted laser to optimize performance, quality and production versatility. The development of ever more advanced laser systems broadens the range of possible applications and benefits.

Which parameters influence the quality of processing?

Each material and application requires a specific laser machine configuration. The main parameters to be considered in programming are:

- Laser power: more or less intense depending on the desired depth or speed

- Engraving speed: affects cycle time and quality of details

- Focusing the laser beam: affects laser accuracy

The OT-LAS laser machines with advanced control system allow customized configurations for each production requirement in order to obtain the best result from the processing.

Why choose an OT-LAS CO2 laser machine

OT-LAS is an Italian company, part of the El.En. group that designs and manufactures high performance laser systems for over 40 years. The deep experience and attention to real customer needs have allowed us to develop unique laser machines for precision and flexibility, entirely Made in Italy.

Investing in a CO2 laser marking and engraving system from OT-LAS means you can count on:

- Reliability over time, thanks to careful design and robust and efficient machinery, made with high quality materials.

- Maximum versatility, as every OT-LAS laser system is designed to guarantee the highest levels of customization and complete production flexibility.

- Production efficiency, thanks to the design designed to reduce energy consumption and optimize performance.

- Extraordinary precision, thanks to the high-definition optical system and the laser head that guarantees high quality finishes and processing for distinctive products.

- Machining also on large formats, with laser machines specially designed to work in a practical and efficient way large plates and surfaces.

To these advantages we add the technical support of OT-LAS to meet the needs of your company with customized configurations and continuous innovation.

Do you want to find out the best machine for your business? Contact us for a personalized consultation.