The demand for laser marking and engraving on large marble and natural stone slabs is growing in several sectors. Architects, designers, cladding manufacturers, and contractors in the construction industry are looking for solutions capable of laser machining large surfaces, often as large as they are valuable. Modern designs require visual continuity of surfaces, which enhances integrity while avoiding unpleasant interruptions.

Advanced customization and sought-after design are two other essential aspects in areas such as interior design and architecture. OT-LAS CO₂ laser technology on large format allows you to engrave large plates precisely, quickly and repeatably, with virtually infinite creative freedom.

Engraving large slabs in wall design and coverings

The CO₂ laser is a fundamental tool in recent years for those working in the world of wall coverings, interior design and furniture. Large marble, stone or ceramic slabs are highly valued in their entirety, with no visible joints that compromise aesthetics. The natural material thus becomes a true architectural and scenographic element, standing out for the beauty of an intact surface. Thanks to laser engraving of slabs it is possible to create:

- Three-dimensional textures

- Continuous patterns even on large areas

- Custom logos, letters and decorative motifs

- Artistic coverings and compositions on multiple meters of surface

- Unique furnishing elements for hotels, SPA, showrooms and luxury residences

The laser does not require mechanical tools to work: this allows for extremely clean processes, where the risk of chipping, breakage or unwanted alterations is very reduced.

Advantages of laser engraving on large surfaces

Working on large slabs brings concrete advantages both aesthetically, strategically and operationally. Among these:

1. Optimization of production processes

A laser machine for large surfaces allows you to:

- reduce manual steps and rework

- eliminate errors resulting from steps due to various processes to obtain the desired decoration

- work the whole surface without resorting to multiple stages and machinery

- ensure consistent and repeatable accuracy

All this significantly speeds up production to the advantage of the final quality of the product and its solidity.

2. Greater creative freedom

Laser processing has virtually no limits in the range of possible effects. Continuous patterns, complex textures, well-defined details finally become easily achievable even on large surfaces.

3. Market expansion

Companies offering large plate engraving can expand their market, meeting the needs of many different entities, including:

- architectural studies

- interior designer

- companies producing ceramics

- custom furniture manufacturers

- luxury contractor

- shipyards and yacht design

All these sectors are often distinguished by large budgets, very specific needs and a growing demand for customization.

4. Superior quality and sustainable processes

Laser marking avoids the typical problems of milling and sandblasting. No tools or masking are required, and precision machining reduces waste production and the risk of material damage. Laser processing is cleaner, greener, and more sustainable because it does not use chemicals that are harmful to the environment and operators.

5. Exclusive work

The ability to offer large custom surfaces paves the way for professional services that increase the profit margins and value offered by the company.

How to laser decorate large plates

The CO₂ laser is an extremely versatile technology that can be used in graphic decorations such as engraving writing and numbers. With a laser machine it is possible to create, for example:

- very complex textures

- detailed graphics

- tone-on-tone effects

- artistic decorations

- technical and functional surface workings, up to 1-2 mm of depth

The speed and advanced technology of professional systems, such as OT-LAS laser machines, allow you to manage large surfaces with perfect continuity in processing. Big slabs, thick and heavy materials can be engraved with impeccable precision. The use of a very high-definition polar optical system, dedicated software and automatic handling systems offer:

- Graphical continuity even on a wide surface

- Repeatability and accuracy of the result

- Ability to combine different effects in the same processing

- Very complex workmanship in terms of detail and customization

- Simplification of production processes

With OT-LAS CO₂ laser, each marble or natural stone slab becomes a unique piece, with high-level results even for prestigious contexts.

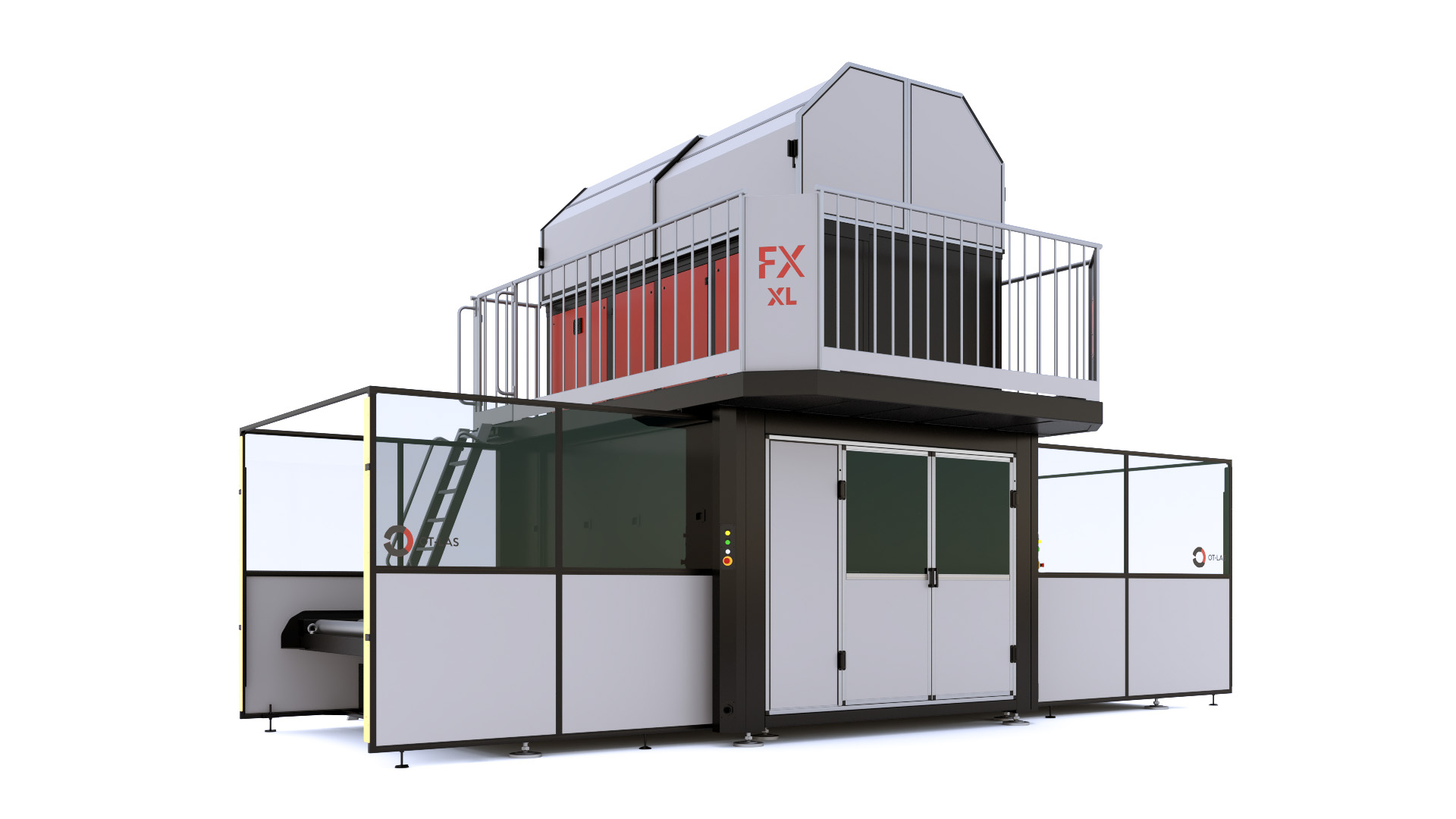

FX XL: the solution for laser engraving on large plates

FX XL by OT-LAS is the most innovative solution for processing marble slabs, ceramics and large natural stones. Designed specifically for these needs, it allows you to easily manage the processing of very large surfaces, thanks to:

- Working area up to 2000 × 3500 mm

- Motorized rollers for easy loading and unloading

- Solid structure and suitable for heavy materials

- HD scanning head for maximum spot accuracy

These features allow for smooth and consistent processing, with maximum flexibility even in the largest sheets. Additionally, the machine is equipped with a radio frequency self-refilling laser source up to 850 W. This ensures:

- Engravings also in depth

- Tone-on-tone markings

- High process speed

- Uniform results even on difficult materials

Which type of materials can be worked with laser?

The FX XL laser machine precisely processes a wide range of materials, such as:

- marble

- granite

- ceramic

- natural stone

- quartz

- slate

- porcelain stoneware

- onyx

- glass

- wood

- malachite

- lapis lazuli

- bricks

- travertine

- agate

The software is designed to create complete files and gestures in geometrical parameters and in the work and operational sequences, which can be easily applied. From professional decoration for furnishings and architecture to the creation of material surfaces for interior design, to the customization of wall coverings. Thanks to FX XL, it is possible to precisely and repeatably decorate even particularly hard materials, such as granite and basalt, maintaining aesthetic continuity.

The benefits of OT-LAS for your business

Choosing OT-LAS laser machines for large surfaces offers you all the advantages of an entirely Made in Italy and quality-oriented supply chain:

- Absolute accuracy

CO₂ OT-LAS laser technology allows for sharp, uniform and flawless incisions even on the most complex surfaces.

- Proven reliability

OT-LAS machines are designed to last, with selected materials and a robust structure suitable for handling heavy materials.

- Made in Italy

All-Italian design and production guarantee you high standards and constant support, with technical assistance, even by remote if needed, from specialized and competent staff.

- Advanced customization

You can request custom configurations and dedicated accessories to adapt the machine to your company’s needs.

- Operational versatility

With OT-LAS machines you can process marble, ceramic, porcelain stoneware, natural stone, wood, glass, plastic, leather, and other materials with a single solution.

Contact us to discover the ideal laser machine for your business.